Are you raising meat birds for your family or as part of a small-scale farming operation? If so, you’re probably aware that timing is everything when it comes to processing your flock. A well-planned timeline can make all the difference in ensuring a successful and efficient harvest. However, with so many factors to consider – from breed selection to growth rates and post-slaughter procedures – it’s easy to get overwhelmed.

In this comprehensive guide, we’ll walk you through everything you need to know to optimize your meat bird processing timeline. We’ll cover topics such as how to choose the right breed for your operation, understanding average growth rates, and navigating post-slaughter procedures. Whether you’re a seasoned farmer or just starting out, our expert advice will help you streamline your process and bring home the bacon (or chicken, rather!) with confidence.

Understanding the Importance of Proper Timing

When it comes to raising meat birds, timing is everything, and getting it right can make all the difference between a successful harvest and a disappointing loss. In this crucial section, we’ll explore the importance of proper timing in the processing timeline.

Key Factors Influencing Processing Timelines

When it comes to meat bird processing timelines, several key factors come into play. Breed selection is one such factor that significantly influences processing times. For example, heritage breeds like Plymouth Rock and Wyandotte tend to take longer to mature, typically requiring an additional 2-3 weeks of growth time compared to commercial breeds. On the other hand, fast-growing breeds like Cornish Cross can be processed in as little as 5-6 weeks.

Environmental conditions also play a crucial role in determining processing timelines. Temperature and humidity levels can impact feed intake and growth rates. In ideal conditions (15-20°C and 50-60% relative humidity), meat birds grow at optimal rates, allowing for earlier processing times. However, if temperatures are extreme or moisture levels are high, growth rates may slow, necessitating longer processing timelines.

In addition to breed selection and environmental conditions, individual bird growth rates can also vary significantly. Some birds may mature faster or slower than their peers due to factors such as nutrition, health, or genetics. Processors must account for this variation when determining processing times to avoid over-processing or under-processing birds.

Determining Optimal Harvest Ages

Determining the optimal harvest age for your flock is crucial to ensure that your meat birds are processed at their peak quality and tenderness. This involves considering several key factors, including weight, size, and overall health.

To determine if your birds are ready for processing, you’ll want to weigh them regularly as they grow. Most meat bird breeds reach their desired weight between 5-10 weeks of age. However, this can vary depending on the breed and production system. For example, slower-growing heritage breeds may not reach market weight until 12-16 weeks.

In addition to weight, you should also assess your birds’ size and overall quality. Look for signs of feather cover, beak development, and leg health. A well-developed beak is essential for the bird’s ability to eat properly after processing. When evaluating size, remember that larger birds are not always better – overgrown birds can be more prone to health issues.

When weighing your birds, consider using a combination of individual weights and averages to determine if they’ve reached market weight. This will help you make an informed decision about when to process them.

Pre-Processing Preparations (Days 1-7)

The first week of processing your meat birds is crucial, and proper planning is essential for a smooth operation. In the following days, we’ll walk you through the key pre-processing preparations to ensure success.

Health Checks and Quarantine Procedures

Performing health checks and quarantine procedures is crucial to ensure that your meat birds are healthy and free from diseases before processing. This step not only helps prevent the spread of disease but also ensures that you’re producing high-quality meat for consumption.

Before conducting health checks, make sure you have a separate isolation area for quarantined birds. This can be a section of your coop or a dedicated quarantine facility. Once you’ve identified any sick birds, isolate them immediately to prevent further transmission.

Conducting daily health checks is essential, and it’s best to do this during the morning when birds are most active. Look for signs of illness such as labored breathing, lethargy, diarrhea, and visible injuries. Take note of any unusual behavior or changes in appetite or water intake.

In addition to visual inspections, consider taking a temperature reading of each flock member. This is especially important if you’re introducing new birds to the flock. Vaccinations should also be administered according to your veterinarian’s recommendations. Some vaccinations may require booster shots at specific intervals, so be sure to follow their schedule carefully.

Sanitation and Equipment Preparation

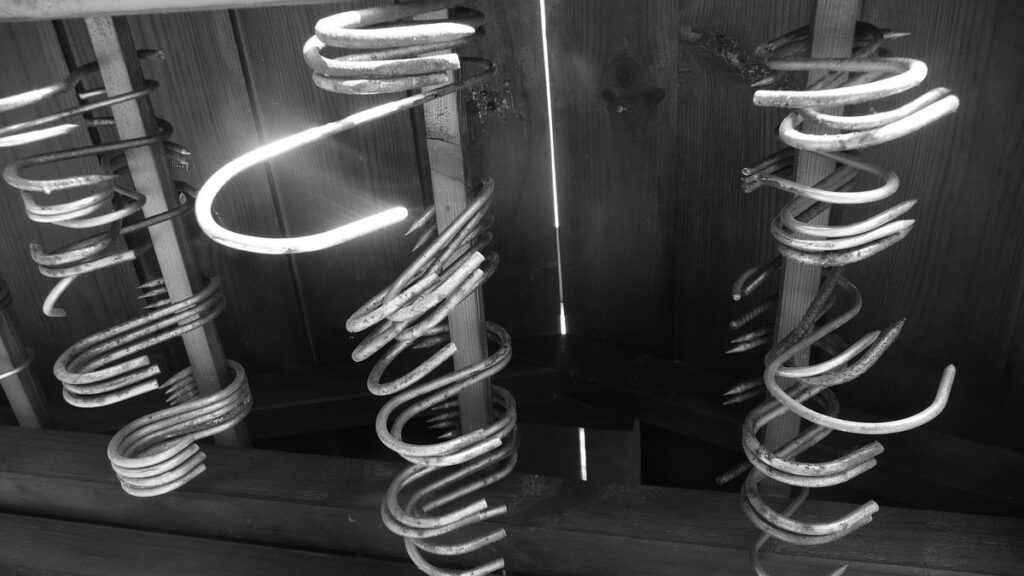

Proper sanitation and equipment preparation are critical steps in the meat bird processing timeline. It’s essential to prioritize cleanliness to prevent contamination and ensure a safe working environment. Start by thoroughly cleaning and disinfecting all equipment, including pluckers, scalders, and deboners. Remove any residual debris or feathers from previous use.

Next, sanitize your work surface with a solution of 1 part bleach to 10 parts water. Allow the surfaces to dry completely before proceeding. If using a new piece of equipment, be sure to follow the manufacturer’s instructions for proper setup and maintenance.

Preparation should also include washing and sanitizing your hands frequently throughout the process. Make it a habit to wash your hands before and after handling birds, as well as between tasks. This practice will help prevent cross-contamination and reduce the risk of illness.

Regular cleaning and disinfection schedules can be implemented to maintain equipment and work surface cleanliness throughout the processing period.

Staging and Resting (Days 8-14)

Now that your meat birds have reached their prime, it’s time to prepare them for slaughter, which involves a crucial staging and resting process. We’ll walk you through this critical period from Days 8-14.

Understanding the Benefits of Staging and Resting

Staging and resting are crucial phases of the meat bird processing timeline, spanning from Day 8 to Day 14. During this period, birds need time to recover from stress caused by handling, vaccinations, and environmental changes. Proper staging and resting allow them to replenish energy reserves, repair tissues, and rebuild their immune systems.

By providing adequate rest, you can reduce stress-related issues like increased mortality rates, decreased weight gain, and compromised feed efficiency. Research suggests that for every day of added recovery time, the risk of disease and mortality decreases by up to 10%. This is especially important during times of high-stress events like transportation or changes in feed.

To implement effective staging and resting strategies:

* Ensure birds have access to clean water at all times

* Maintain a balanced diet that supports energy replenishment

* Provide a comfortable, stress-free environment with adequate ventilation and space

* Monitor temperature fluctuations and maintain optimal ranges (around 70-75°F) to conserve energy

Maintaining Flock Health During Staging and Resting

Maintaining flock health during staging and resting periods is crucial to prevent disease outbreaks and ensure a high-quality final product. During this time, it’s essential to monitor the birds’ behavior, diet, and environment closely.

Provide an adequate supply of fresh water and maintain proper ventilation within the coop to prevent ammonia buildup. A clean and well-ventilated environment can help reduce stress levels in the flock, which is critical during staging and resting periods.

Monitor for any signs of disease or illness, such as changes in appetite, droppings, or feather condition. Isolate any affected birds promptly to prevent the spread of disease among the rest of the flock.

Keep an eye on feed consumption and adjust feeding schedules accordingly to maintain optimal energy levels. Avoid overfeeding, which can lead to digestive issues and other health problems.

Regularly inspect the coop for signs of pests, such as mites or lice, and take corrective action if necessary. By maintaining a clean and healthy environment, you can minimize the risk of disease outbreaks and ensure a strong, healthy flock at the end of the processing timeline.

Slaughtering and Evisceration (Days 15-21)

Between days 15 and 21, you’ll be processing your meat birds from slaughter to evisceration, a critical step in preparing them for market. This section will guide you through this crucial process.

Preparing for Slaughter: Equipment and Personnel Needs

As you approach the slaughtering and evisceration phase of meat bird processing, it’s essential to ensure that you have the necessary equipment and personnel to carry out this critical step. This process requires a specific set of tools, including a stunning gun or captive bolt pistol, a scalding tank, and evisceration tables.

In terms of personnel, you’ll need experienced staff who are trained in humane slaughter techniques and have knowledge of food safety protocols. At least two people should be present during the slaughtering process: one to carry out the actual slaughter and another to monitor and oversee the operation. Ensure that all personnel are aware of the importance of maintaining a clean environment, handling birds gently to minimize stress, and adhering to strict hygiene standards.

Proper equipment maintenance is also crucial. Regularly inspect your tools for wear and tear, and replace them as needed. Additionally, ensure that your scalding tank is cleaned and maintained according to manufacturer guidelines to prevent bacterial contamination.

The Importance of Humane Handling During Slaughter

When it comes to slaughtering and eviscerating meat birds, humane handling is crucial to minimize stress on the birds. Stress can lead to a range of issues, including decreased quality of the final product and potential food safety risks.

Stressed birds are more likely to experience physical reactions such as struggling, panting, or even fainting during slaughter. These reactions not only compromise the bird’s welfare but also make the slaughtering process more challenging for handlers. In extreme cases, stress can even lead to a condition known as “choking death,” where the bird’s airway becomes obstructed due to excessive struggling.

To ensure humane handling during slaughter, it’s essential to maintain calm and composed birds throughout the entire process. This can be achieved by providing a clean, well-ventilated environment and ensuring that birds are handled gently and carefully. Trained personnel should oversee the slaughtering process, monitoring bird behavior and taking steps to minimize stress whenever possible.

By prioritizing humane handling during slaughter, you can help maintain the quality of your meat birds while also upholding animal welfare standards.

Post-Slaughter Processing (Days 22-28)

As we approach the final stages of processing, this crucial period focuses on transforming raw meat into high-quality products suitable for market. Let’s take a closer look at these critical days in the timeline.

Cooling and Storage Requirements for Meat Birds

Proper cooling and storage are critical steps that must be executed with care to preserve the quality of meat bird products. As soon as possible after slaughter, it’s essential to cool the birds to a temperature below 40°F (4°C) within two hours and to 32°F (0°C) within four hours. This rapid cooling process, also known as “chilling,” helps prevent bacterial growth and maintains texture.

To ensure efficient cooling, consider investing in a cold storage unit or renting one if you don’t have access to the necessary equipment. Keep in mind that air circulation is vital during this stage; it not only helps speed up the cooling process but also prevents moisture accumulation on the carcasses. Regularly check temperature gauges and adjust your setup as needed.

When storing meat bird products, label containers clearly with date, time, and contents to prevent mix-ups. Ensure that storage facilities are well-ventilated, dry, and maintained at a consistent refrigerated temperature below 40°F (4°C). Store raw meat separate from ready-to-cook or ready-to-eat products to minimize cross-contamination risks.

Labeling and Packaging Procedures

Labeling and packaging procedures are crucial aspects of post-slaughter processing, as they ensure compliance with regulations and maintain the quality and integrity of the final product. On day 22-28, after slaughter, meat birds are labeled and packaged according to specific guidelines.

Proper labeling involves including essential information such as the name of the establishment, the species of bird, the type of cut or product, and any relevant handling instructions. This information must be legible, accurate, and in a format that complies with regulations set by the USDA (United States Department of Agriculture) and other governing bodies.

When it comes to packaging, meat birds are typically wrapped individually or grouped together, depending on the type of cut or product. Packaging materials should be food-grade and designed specifically for use in the poultry industry. To prevent contamination and maintain quality, packaging should be done promptly after processing, and any exposed cuts or surfaces should be covered or sealed.

In addition to these general guidelines, it’s essential to follow specific regulations regarding labeling and packaging procedures. For example, meat birds destined for human consumption must be labeled as “Ready-to-cook” or “Cooked,” while those intended for further processing may require different labels.

Marketing and Sales Strategies (After Day 28)

Now that you’ve processed your birds, let’s dive into marketing and sales strategies to ensure a smooth transition from farm to table. This includes tactics for promoting your products after day 28.

Navigating Regulations and Labels

As you navigate the meat bird processing timeline, it’s essential to consider the regulations and labels that impact your business. In the US, for instance, the USDA regulates labeling, while the FDA oversees claims related to nutritional content. Familiarize yourself with these agencies’ guidelines to avoid costly mistakes.

When it comes to labels, accuracy is crucial. Consumers expect clear information about product origin, handling practices, and nutrition facts. For example, if your birds are raised without antibiotics, make sure this claim is prominently displayed on packaging. Similarly, if you’re highlighting the environmental benefits of your operation, ensure these claims are substantiated.

To stay compliant, keep detailed records of your production process, including feed, processing, and storage practices. This documentation will be invaluable when responding to label inquiries or audit requests from regulatory bodies. Regularly review industry publications and attend workshops to stay up-to-date on evolving regulations and labeling requirements.

Building a Customer Base Through Storytelling and Branding

As you navigate the meat bird processing timeline, it’s easy to get caught up in the technical aspects of production. However, building a strong customer base is crucial for long-term success. This is where storytelling and branding come into play.

Think about it: consumers are no longer just looking for a product; they’re seeking an experience. They want to know the story behind their food, from the farm to the table. By sharing your unique narrative, you can differentiate yourself in a crowded market and build trust with potential customers.

Consider using social media platforms to share stories about your farm’s history, values, and practices. Highlight your commitment to sustainability, animal welfare, and quality control. Use high-quality visuals to showcase your products and the people behind them. For instance, you could create a video series showcasing the care and attention that goes into raising your meat birds.

By weaving these stories throughout your branding efforts, you’ll not only attract new customers but also retain existing ones who appreciate your transparency and authenticity.

Conclusion: Maximizing Efficiency in Meat Bird Processing

Now that you’ve navigated the meat bird processing timeline, let’s wrap up by exploring practical ways to optimize your workflow and boost efficiency. This section reveals expert strategies for achieving peak productivity.

Recap of Key Takeaways

In this recap of key takeaways, we’ll summarize the essential points from our comprehensive guide to the meat bird processing timeline. As you now understand the critical steps involved in efficiently processing your flock, let’s revisit the most important details.

When it comes to planning and executing a smooth processing operation, timing is everything. Properly managing each step of the process can significantly reduce stress on both yourself and your birds. This includes ensuring adequate equipment and supplies are available beforehand. Consider investing in automated systems for tasks like evisceration or feather removal to streamline operations.

Additionally, understanding the ideal bird weight and growth rate for your specific breed is crucial. This information will help you schedule processing at the optimal time, reducing waste and improving overall efficiency. Regularly monitoring your birds’ development and adjusting your timeline accordingly will also contribute to a smoother process. By applying these key takeaways, you’ll be well-prepared to navigate the complexities of meat bird processing and optimize your operation for success.

Future Directions for Optimization

As we conclude our exploration of the meat bird processing timeline, it’s clear that there are still opportunities for optimization. With the ever-increasing demand for meat and poultry products, processors must remain vigilant in their pursuit of efficiency.

One promising area of research is the application of artificial intelligence (AI) and machine learning (ML) to predict and prevent processing bottlenecks. By analyzing historical data and real-time production metrics, AI-powered systems can identify trends and patterns that may indicate potential slowdowns or capacity issues. This allows processors to proactively adjust their schedules, staffing, and resources to maintain optimal throughput.

Another area ripe for innovation is the integration of automation technologies such as robotics, vision inspection systems, and sorting equipment. These tools can significantly enhance processing speed and accuracy while reducing labor costs and minimizing waste. For example, robotic grading systems can quickly and accurately sort carcasses by weight and quality, freeing up human inspectors to focus on more critical tasks.

By embracing these emerging technologies and staying ahead of the curve, meat bird processors can continue to drive efficiency gains, improve product quality, and stay competitive in an increasingly demanding market.

Frequently Asked Questions

How Do I Determine the Optimal Harvest Age for My Flock?

The optimal harvest age depends on several factors, including breed, growth rate, and desired meat quality. Generally, meat birds are ready to process between 5-7 weeks of age. However, it’s essential to check their weight and conformation regularly to ensure they reach your target size. For example, if you’re raising heritage breeds, you may need to harvest them at an older age (around 9-10 weeks) for optimal flavor and texture.

What Happens If I Miss the Optimal Harvest Age?

If you miss the optimal harvest age, it can affect the quality of your meat. Meat birds that are over- or under-developed may not have the best taste, texture, or presentation. In such cases, you may need to adjust your processing timeline accordingly. For instance, if your flock is ready too early, you might consider delaying slaughter for a few days to ensure optimal weight and conformation.

How Do I Prepare My Equipment and Team for Slaughter?

Proper preparation is crucial for efficient and humane slaughter. Ensure that all equipment, including knives, saws, and slaughter guns, are clean, sanitized, and in good working condition. Train your team on proper handling, restraint, and killing techniques to minimize stress and ensure a smooth process.

Can I Use My Existing Coop or Facilities for Processing?

Using existing coops or facilities can be cost-effective, but it’s essential to consider the logistics and sanitation requirements of processing. Ensure that your coop or facility is clean, well-ventilated, and equipped with necessary tools and equipment for safe and efficient slaughter. Consider investing in specialized processing equipment, such as a mobile evisceration unit, if you plan to process large quantities.

How Do I Store and Handle the Meat After Processing?

After processing, it’s crucial to store and handle the meat properly to maintain quality and safety. Use clean, sanitized containers or bags for storage, and keep them at a consistent refrigerated temperature below 40°F (4°C). Label and date all packages clearly, and ensure that they are stored in a dry, well-ventilated area to prevent spoilage and contamination.