As a turkey breeder or enthusiast, you’re probably well aware that proper incubation is crucial for successful hatching. But among the many factors to consider, maintaining optimal humidity levels can be particularly challenging. You see, humidity affects not just the embryo’s development but also its chances of survival and hatch rate. That’s why getting it right is so important. In this article, we’ll delve into the world of turkey egg incubation humidity, exploring what levels are ideal, how to monitor and record them, and most importantly, how to adjust for maximum results. Whether you’re a seasoned breeder or just starting out, understanding the secrets to optimal humidity will help you achieve higher hatch rates and healthier chicks.

Understanding the Importance of Humidity in Turkey Egg Incubation

Proper humidity levels play a vital role in turkey egg incubation, and understanding its importance can make all the difference in achieving healthy hatch rates. Let’s dive into what you need to know.

Factors Affecting Embryo Development and Hatch Rate

Maintaining optimal humidity levels is crucial for successful turkey egg incubation. The humidity level impacts embryo growth, development, and hatch rates significantly. When the humidity is too low, the eggs may dry out, causing a decrease in fertility and hatchability.

On the other hand, high humidity can lead to mold growth and bacterial contamination. This can result in embryonic death or stillbirths. To achieve optimal embryo development, it’s essential to maintain a consistent relative humidity (RH) level between 50-60% for the first 18 days of incubation. After day 18, the RH should be increased to 70%.

A study on turkey egg incubation found that eggs incubated at an average RH of 55% had significantly higher hatch rates compared to those incubated at lower or higher humidity levels. In practical terms, this means that you need to monitor your incubator’s temperature and humidity settings closely during the incubation period.

To ensure optimal embryo development, it is recommended to adjust the humidity setting every 24 hours based on the ambient temperature. This can be done by turning off the humidifier for a few hours or adjusting its output as needed. By maintaining the correct humidity levels, you’ll significantly improve your chances of successful hatching and healthy chicks.

The Role of Relative Humidity in Preventing Dehydration

When it comes to maintaining optimal incubation conditions for turkey eggs, relative humidity plays a crucial role in preventing dehydration. Embryos develop rapidly during the first 24-48 hours after fertilization, and if the air is too dry, they can quickly dehydrate, leading to stalled or failed development.

Relative humidity helps maintain an ideal moisture balance around the embryo, ensuring healthy growth and development. When the relative humidity is within the optimal range (around 50-60%), the eggs breathe efficiently, releasing excess carbon dioxide and absorbing oxygen. This process helps regulate embryonic metabolism, supporting the production of vital energy sources.

Aiming for a relative humidity level between 50-60% can help prevent dehydration by:

• Reducing water loss from the embryo

• Maintaining optimal metabolic activity

• Supporting healthy development and growth

• Minimizing the risk of embryonic death

Monitoring and adjusting the incubator’s relative humidity levels will help you achieve these benefits, giving your turkey eggs a solid foundation for successful hatching. By paying attention to this critical factor, you’ll be well on your way to raising healthy, robust poults.

Setting Up a Proper Incubator Environment

Proper incubation environment starts with setting up your equipment and creating a stable space for consistent temperature and humidity control. This means carefully selecting the right equipment to ensure accurate readings.

Choosing the Right Incubator and Accessories

When it comes to choosing the right incubator for turkey eggs, there are several factors to consider. First and foremost, you’ll want an incubator that’s specifically designed for poultry, as these units will typically have features such as automatic egg turning, temperature control, and humidity management.

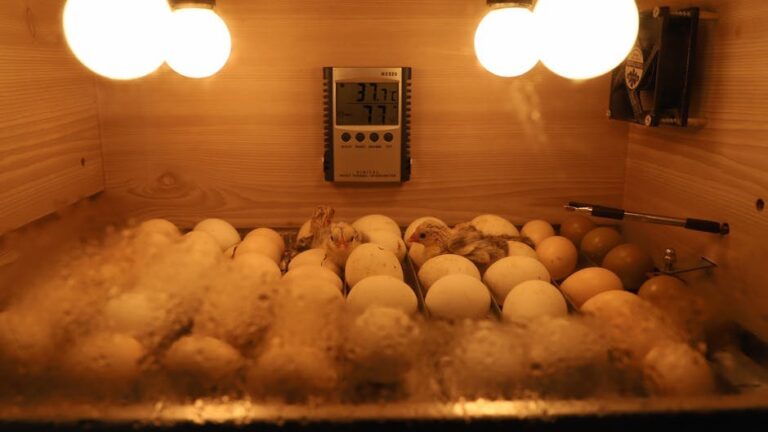

In terms of essential accessories, you’ll need a reliable thermometer to ensure the accurate maintenance of optimal temperatures (around 99-100°F). A hygrometer is also crucial for monitoring the incubator’s humidity levels, which should be between 50-60% during the first 24 days of incubation.

An egg turner is another must-have accessory, as it will help to simulate the natural turning process that occurs in a broody hen‘s nest. This is especially important for turkey eggs, which require frequent turns to prevent sticking and promote even development.

When selecting an incubator, also consider its power source – some models run on electricity while others are designed for use with gas or kerosene. Be sure to choose a model that meets your specific needs and is compatible with the accessories you plan to use.

Installing and Calibrating the Hygrometer

Installing and calibrating a hygrometer is crucial to maintain optimal humidity levels within your turkey egg incubator. Before you begin, ensure that the hygrometer you choose is specifically designed for incubation use, as these devices are more accurate than general-purpose hygrometers.

First, install the hygrometer in the incubator according to the manufacturer’s instructions. Typically, this involves attaching the device to the incubator wall or placing it within the incubator itself. Be mindful of air currents and draft, which can affect the accuracy of your readings.

Calibration is a more involved process. You’ll need to adjust the hygrometer’s settings based on its sensitivity range (usually between 20% and 80% relative humidity). Start by setting the hygrometer to the middle point (50%) of its range. Next, place the device in a sealed container with a saturated salt solution (available at most science supply stores) that matches the desired humidity level.

Monitor the hygrometer for 24 hours, allowing it to stabilize and adjust to its new environment. Once calibrated, ensure that the incubator’s humidity settings are set within the optimal range of 45-55% relative humidity during the first 18 days of incubation. By following these steps, you can accurately install and calibrate your hygrometer to provide precise humidity readings for successful turkey egg incubation.

Maintaining Optimal Humidity Levels During Incubation

Maintaining optimal humidity levels is crucial during incubation, as it affects embryo development and hatch rates. Let’s dive into the strategies for achieving precise moisture control in your turkey egg incubator setup.

Monitoring and Recording Temperature and Humidity Data

Monitoring temperature and humidity data is crucial to ensure optimal conditions for turkey egg incubation. A slight deviation from ideal levels can lead to poor hatch rates, weak chicks, or even embryo mortality. To avoid these issues, it’s essential to invest in a reliable thermometer and hygrometer that can provide real-time readings.

You should place the thermometer near the eggs, ideally at the same level as the egg trays. This will ensure accurate temperature recordings. As for humidity, you’ll want to place the hygrometer away from drafts but still within the incubation chamber. Regularly check both devices and record the data in a logbook or spreadsheet.

It’s also vital to set up a data collection system that allows you to track temperature and humidity fluctuations over time. This will enable you to identify any patterns or issues early on, making it easier to make adjustments as needed. Some incubators come equipped with built-in monitoring systems, while others require external devices. Familiarize yourself with your specific equipment to ensure smooth data collection and analysis.

Adjusting Humidity Levels as Necessary

Adjusting humidity levels as necessary is crucial to ensure optimal embryo development. Temperature fluctuations can significantly impact humidity requirements, so it’s essential to monitor temperature changes closely. As a general rule of thumb, for every 1°F (0.5°C) increase in temperature, the relative humidity should be decreased by approximately 2-3%. Conversely, for each 1°F (0.5°C) decrease in temperature, the relative humidity should be increased by about 2-3%.

For example, if you’re incubating at a steady temperature of 99°F (37.2°C), maintaining 50% relative humidity is ideal. However, if the temperature suddenly increases to 100.5°F (38°C), you’d need to lower the humidity to around 45-47%. Similarly, if the temperature drops to 98°F (36.7°C), you may want to increase the humidity to 55-57%.

Keep in mind that these are general guidelines, and specific conditions may vary depending on your incubation setup. It’s crucial to monitor temperature and humidity levels closely and make adjustments as needed to ensure optimal embryo development. By doing so, you’ll be well on your way to successfully incubating healthy turkey eggs. Regularly checking the temperature and making necessary adjustments will help maintain an optimal environment for your embryos to grow and develop.

Troubleshooting Common Issues Related to Humidity

Don’t let humidity-related problems derail your turkey egg incubation – this section tackles common issues and provides practical solutions to get you back on track.

Recognizing Signs of Over- or Under-Humidity

When it comes to maintaining optimal humidity levels during turkey egg incubation, recognizing signs of over- or under-humidity is crucial. Excessive moisture can lead to fungal growth and mold development on the eggs or incubator surfaces, which can be detrimental to embryonic health.

Common indicators of over-humidity include visible fungal growth, a musty odor, or a sticky residue on the incubator walls. On the other hand, under-humidity can cause eggs to crack due to desiccation, leading to embryo mortality. This may also result in dry, shriveled egg membranes that can be easily torn.

If you notice any of these signs, it’s essential to adjust your humidity settings accordingly. Aim for a relative humidity (RH) range between 40% and 60%. To maintain this balance, monitor temperature fluctuations closely, as even slight changes can impact humidity levels. Regularly inspect the incubator and eggs for signs of moisture-related issues, and make adjustments promptly to prevent potential problems.

Strategies for Correcting Humidity-Related Problems

When you notice that humidity levels are off during turkey egg incubation, it’s essential to address the issue promptly. Here are some strategies for correcting humidity-related problems:

Firstly, monitor temperature fluctuations alongside humidity changes. A slight increase or decrease in temperature can affect humidity levels. Use a thermometer and hygrometer in close proximity to the eggs to track these changes.

Next, assess your incubator’s ventilation system. Proper airflow is crucial for maintaining optimal humidity levels. Ensure that air is circulating through the incubator evenly, without creating drafts that could disrupt egg development. If necessary, adjust the number of vents or relocate the incubator to an area with better airflow.

In some cases, high humidity may lead to mold growth on the eggs or inside the incubator. Use a sanitizing solution specifically designed for this purpose to clean and disinfect the affected areas. This will help prevent fungal infections that could compromise egg viability.

Advanced Techniques for Monitoring and Controlling Humidity

To take your turkey egg incubation game to the next level, you’ll want to learn advanced techniques for monitoring and controlling humidity levels in your brooder. This section will walk you through those essential methods.

Using Data Loggers and Automated Systems

Using data loggers and automated systems can take your turkey egg incubation humidity monitoring to the next level. These tools allow for precise control and real-time monitoring of temperature and humidity levels within the incubator.

Data loggers, which record temperature and humidity readings at set intervals, provide a detailed history of conditions throughout the incubation period. This information is invaluable in identifying any issues or inconsistencies that may impact hatch rates. Automated systems, on the other hand, enable you to maintain optimal humidity levels without manual intervention.

For example, an automated system can be programmed to increase humidity levels as eggs approach hatching. This ensures that chicks are met with a stable and humid environment upon emergence. Many modern incubators come equipped with built-in data loggers and automation capabilities, making it easier than ever to monitor and control conditions.

When selecting a data logger or automated system, consider the following factors: ease of use, connectivity options (e.g., Wi-Fi, Bluetooth), and compatibility with your existing equipment. With these advanced tools in place, you’ll be well-equipped to maintain optimal humidity levels throughout the incubation period.

Integrating Humidity Control with Other Incubator Functions

When it comes to optimizing turkey egg incubation conditions, integrating humidity control with other critical functions is crucial for successful hatching. This means synchronizing temperature regulation and egg turning with humidity levels to create a stable and favorable environment.

To achieve this synergy, start by programming the incubator’s controls to adjust temperature in response to changes in humidity. For example, as humidity rises above 50%, the thermostat can automatically reduce the temperature to prevent overheating. Conversely, when humidity drops below 40%, the incubator can increase the temperature slightly to maintain optimal conditions.

Egg turning is another essential function that must be coordinated with humidity control. Research has shown that even slight changes in temperature and humidity during incubation can affect chick development and hatchability. By integrating egg turning with humidity levels, you can minimize these risks and ensure that your turkey eggs receive the ideal conditions for hatching.

Conclusion: Maximizing Turkey Egg Hatch Rates Through Optimal Humidity Levels

In conclusion, achieving optimal humidity levels is crucial for maximizing turkey egg hatch rates. By understanding the ideal range of 45-50% relative humidity during incubation, you can significantly improve the chances of healthy hatching. It’s essential to maintain consistent humidity levels throughout the incubation period to prevent water loss and promote embryonic development.

To maximize hatch rates, make sure to monitor the temperature in conjunction with humidity levels, as a slight imbalance between the two can have a negative impact on the eggs. Regularly checking and adjusting the humidity levels will help you fine-tune your incubation process, ensuring optimal conditions for hatching. With practice and patience, you’ll be able to achieve consistent hatch rates, giving you more confidence in your turkey egg incubation endeavors.

Frequently Asked Questions

How do I know if my incubator’s humidity settings are accurate?

Make sure to follow the manufacturer’s instructions for calibrating your hygrometer, as even small errors can impact hatch rates. You can also use a separate, independent hygrometer to double-check your readings.

What happens if I don’t have access to a data logger or automated system for monitoring humidity?

You can still achieve optimal results by regularly checking and recording the humidity levels manually. However, be aware that this method requires more attention and may lead to potential errors.

How often should I adjust the humidity levels in my incubator?

It’s essential to monitor temperature and humidity levels closely, especially during critical stages of incubation (e.g., Day 3-5). Adjustments may be necessary every few hours or as needed based on your specific setup and environmental conditions.

Can I use a regular humidifier for maintaining optimal humidity in my incubator?

While some humidifiers work well, it’s crucial to choose one specifically designed for use with poultry incubators. These models can provide precise control and prevent potential issues like over-humidification or bacterial growth.

What are the signs of under- or over-humidity that I should watch out for during incubation?

Keep an eye on embryo development, fertility rates, and hatchability. Under-humidity may lead to dehydration, while over-humidity can cause mold growth or bacterial contamination. Monitor your data loggers or manual records closely to identify any issues early on.