Meat chicken processing can be a daunting task for anyone, from seasoned farmers to backyard producers. With the right preparation and knowledge, however, you can ensure a smooth and efficient process that results in high-quality products. One crucial aspect of meat chicken processing is pre-processing day prep – getting everything ready before the actual processing takes place. This includes preparing equipment, organizing supplies, and most importantly, maintaining food safety and quality control throughout the entire process.

In this article, we’ll walk you through the essential steps and techniques for a successful meat chicken processing day prep. From pre-processing to post-processing, we’ll cover everything you need to know to achieve consistent results and meet regulatory requirements. Whether you’re looking to improve your existing operation or just starting out, our guide will provide you with the knowledge and confidence to tackle even the most challenging tasks. By following these tips, you can reduce stress, increase productivity, and ultimately produce better chicken products that meet the highest standards of food safety and quality control.

Understanding Meat Chicken Processing Basics

Meat chicken processing involves several key steps that ensure a smooth and efficient operation, starting from receiving live birds to final packaging. Let’s break down these essential tasks together!

Importance of Proper Preparation

Proper preparation is crucial on a meat chicken processing day. It’s not just about getting through the tasks at hand; it’s also about ensuring that every bird processed meets quality and safety standards.

When it comes to food safety, one of the most significant considerations is preventing cross-contamination. This can be achieved by dedicating specific equipment for specific tasks, like a designated knife or cutting board for each station. It may seem time-consuming, but trust me, it’s worth the extra effort. For example, if you’re handling raw chicken, make sure to sanitize all surfaces and equipment before moving on to processing beef or pork.

To maintain quality control, it’s essential to have a clear understanding of what’s expected from each bird. This includes factors like weight, grade, and yield. Knowing these details upfront helps prevent errors during the processing stage, which can lead to waste, financial losses, and compromised product quality.

Types of Meat Chicken Processing Methods

When it comes to meat chicken processing, various methods are used depending on the desired product and level of convenience for consumers. Whole bird processing involves cutting the raw chicken into whole birds, which can then be packaged and sold as is. This method preserves the natural anatomy of the bird and retains more nutrients compared to further processed products.

Deboning, on the other hand, removes all bones from the carcass, resulting in a leaner product with less waste. This process requires specialized equipment but increases efficiency for larger production runs. Further processing steps like slicing or dicing transform raw chicken into convenient pre-cut portions ideal for cooking. These cuts can be made mechanically or manually and are commonly used in commercial settings.

Some establishments may also choose to boneless processing, where the meat is separated from the bones without removing them entirely. This method offers a balance between convenience and nutritional retention. Ultimately, selecting the right chicken processing method depends on business goals, production capacity, and target market demands.

Common Equipment Used in Meat Chicken Processing

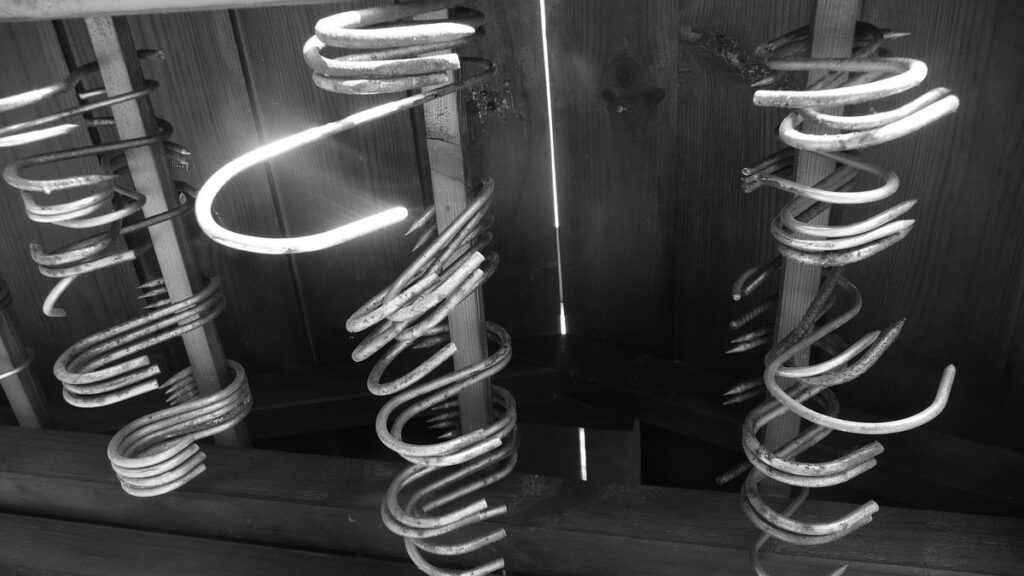

On a meat chicken processing day, several pieces of equipment come together to ensure efficient and hygienic production. Grinders are one of the most crucial tools used for breaking down raw meat into uniform sizes suitable for further processing. These machines can be electric or manual, depending on the scale of operation, and typically consist of multiple grinding stages that progressively reduce the size of the meat particles.

Slicers, another essential piece of equipment, are designed to slice thin cuts of meat quickly and accurately. These machines usually have adjustable thickness settings to accommodate various types of products. When selecting a slicer for your operations, consider factors such as capacity, speed, and ease of cleaning.

Packaging machinery is also vital in the processing stage, as it ensures that the final product meets quality standards and safety regulations. This includes equipment like tray sealers, packaging machines, and label applicators, which work together to enclose the sliced meat in a protective layer while maintaining its freshness and appearance.

Some other common equipment used in meat chicken processing include vacuum sealers for removing air from packaging, blast freezers for rapid freezing, and metal detectors or X-ray machines for detecting foreign objects.

Pre-Processing Steps: Cleaning and Preparation

Before we dive into the processing steps, it’s essential to get your chickens clean and ready for handling. This involves prepping their feathers, beaks, and feet.

Sanitation and Cleaning Procedures

Sanitation and cleaning procedures are crucial components of meat chicken processing day prep. Before starting any tasks, it’s essential to ensure a clean and sanitized environment to prevent contamination and maintain product quality.

Regular cleaning schedules should be implemented to maintain a clean facility. This includes daily cleaning of equipment, floors, and walls with a focus on high-touch areas such as sink handles, faucets, and door handles. A designated person or team can be responsible for this task to ensure it’s done consistently.

Proper waste disposal methods are also vital in preventing cross-contamination. All organic waste should be disposed of immediately after use and stored in sealed containers until collection. In addition, regular deep cleaning is necessary, typically performed on a weekly or bi-weekly basis, depending on the facility’s traffic and production volume.

It’s also essential to establish a sanitation and cleaning checklist to ensure all areas are properly cleaned and sanitized before starting processing tasks. This includes routine cleaning of equipment and machinery, such as broilers and cutting tools, as well as storage areas and receiving dock.

Deboning and Trimming Techniques

Deboning and trimming are crucial steps in meat chicken processing that require precision and attention to detail. There are two primary methods used for deboning: hand removal and mechanical tools.

Hand removal involves skilled laborers carefully extracting bones from the carcass using specialized knives or cutters. This technique is often employed when a high level of quality control is necessary, such as in organic or specialty chicken production. To achieve optimal results, operators must follow strict sanitation procedures to prevent contamination and maintain product integrity.

Mechanical tools, on the other hand, utilize automated deboning machines that rapidly strip bones from the meat. These machines can significantly increase processing efficiency while maintaining accuracy. However, they do require regular maintenance and calibration to ensure precise bone removal. By combining both methods, processors can optimize their workflow, reduce labor costs, and meet customer demands for high-quality chicken products.

In practice, deboning accounts for approximately 20% of the total processing time in a standard chicken plant. Effective deboning techniques not only enhance product quality but also contribute to overall operational efficiency.

Initial Inspection and Grading

When it’s time to start processing chicken meat, quality control is crucial to ensure that only the best products make it to market. This begins with an initial inspection and grading process that sets the tone for everything else that follows.

Inspectors will carefully examine each bird, checking for visible defects such as bruising, bleeding, or torn skin. They’ll also look for signs of contamination, like dirt, debris, or fecal matter. Any birds deemed unfit for processing are immediately removed from the production line and set aside for further evaluation.

To give you a better idea, let’s say we have a batch of 1000 chickens arriving at our facility. Upon initial inspection, we might identify around 20-30 birds with visible defects or contamination issues. These would be set aside for re-processing or destroyed altogether to prevent any potential harm to consumers.

Day-Prep Activities: Setting Up for Production

When it comes to a successful meat chicken processing day, preparation is key. Let’s dive into the crucial day-prep activities that set you up for production success.

Setting Up Processing Equipment

Setting up processing equipment is a critical step in preparing for a successful chicken processing day. It requires attention to detail and a thorough understanding of each machine’s specifications and requirements.

First, it’s essential to familiarize yourself with the layout of the processing floor, taking note of the location of all equipment, including the chiller, boner, and packaging machines. This will ensure that everything is easily accessible and within reach. Next, carefully read through the manufacturer’s guidelines for each machine, paying particular attention to calibration procedures.

Proper calibration is crucial for achieving optimal performance from your equipment. Calibration involves adjusting various settings, such as conveyor belts, cutting blades, and temperature controls, to guarantee precise and consistent results. This may involve using digital tools or manually measuring parameters like blade thickness or pressure.

To avoid last-minute rush and potential damage to equipment, it’s recommended to perform a trial run with each machine before the actual processing day. This will help identify any issues and allow for adjustments to be made accordingly.

By taking the time to properly set up your processing equipment, you’ll ensure a smoother, more efficient operation that meets all safety and quality standards. Regular maintenance and calibration checks can also prevent costly repairs and minimize downtime in the long run.

Preparing Packaging Materials

Preparing packaging materials is an essential day-prep activity that ensures efficient and accurate product labeling. Labels, bags, and trays are crucial components of meat chicken processing, as they provide critical information to consumers about the product’s contents, weight, and storage instructions.

To prepare labels, it’s vital to double-check that all necessary information is included, such as the establishment number, package weights, and any relevant allergen or nutritional warnings. Make sure to have a sufficient stock of labels on hand to avoid last-minute scrambles during production.

For bags and trays, ensure they are properly cleaned and sanitized before filling them with product. This step may seem minor, but it can significantly impact the overall quality and safety of your final packaged products. Consider investing in reusable containers or bags to reduce waste and save resources.

When preparing packaging materials, remember to also plan for contingencies, such as labeling errors or equipment malfunctions. Having a backup plan in place will help minimize downtime and ensure your products are labeled accurately and efficiently.

Organizing Workstations and Flow

When it comes to organizing workstations and production flow in meat chicken processing, a well-planned setup can make all the difference. Start by assigning specific tasks to each workstation, taking into account the sequence of operations and the equipment required for each task. This will help minimize downtime and reduce waste.

For example, place the evisceration station near the receiving area to streamline the process and prevent unnecessary handling of birds. The deboning table should be positioned near the packaging area to enable efficient wrapping and labeling. Consider implementing a ‘first in, first out’ system to ensure older products are processed before newer ones.

To further optimize flow, designate clear paths for product movement and assign adequate space for staff to move comfortably between stations. Implement visual cues such as color-coded labels or signs to guide staff through the production process. Regularly review and adjust your workstation layout as needed to prevent bottlenecks and ensure smooth operation throughout the day. By investing time in upfront planning, you’ll set yourself up for success and reap significant productivity gains.

In-Process Quality Control: Monitoring and Adjusting

As we dive into the meat chicken processing day prep, let’s take a closer look at how quality control measures are implemented to ensure every bird meets our high standards. We’ll explore monitoring and adjusting techniques in real-time.

Regular Cleaning and Sanitation Schedules

Maintaining a clean and sanitized environment is crucial throughout the meat chicken processing day to prevent contamination and ensure food safety. Regular cleaning and sanitation schedules for equipment, tools, and work areas must be strictly adhered to. This includes daily tasks such as sanitizing knives, cleavers, and other cutting instruments after each use.

Cleaning of equipment like conveyor belts, pumps, and machinery should also be done regularly. Scheduling this task helps ensure that all critical parts are properly cleaned and sanitized before they can potentially contaminate the product being processed. Cleaning schedules for work areas, including floors, walls, and storage spaces, should be implemented to prevent cross-contamination.

Cleaning supplies such as sanitizing solutions, detergents, and disinfectants must also be readily available and easily accessible throughout the processing facility. It’s essential that cleaning tasks are distributed among staff members with clear responsibilities assigned for each task. Training on proper sanitation procedures is also necessary to ensure all employees adhere to these guidelines, which can help prevent costly recalls due to contamination.

Monitoring Temperature and pH Levels

Monitoring temperature and pH levels is crucial during meat chicken processing to ensure optimal conditions for food safety and quality. Temperature control is vital as bacterial growth accelerates rapidly between 40°F (4°C) and 140°F (60°C). For example, if the product is stored at a temperature above 45°F (7°C), it may not meet regulatory requirements, which can lead to costly rework or even product rejection.

Temperature monitoring typically involves using thermometers, data loggers, or online monitoring systems to track temperature fluctuations throughout the processing line. Similarly, pH levels must be carefully monitored to prevent contamination and spoilage. A pH range of 4.2 to 7 is generally considered safe for meat chicken products.

Practical advice would be to conduct regular checks on both temperature and pH levels, ideally every 30 minutes or as per plant protocol. This ensures that any deviations from optimal conditions can be quickly identified and corrected, minimizing the risk of contamination and maintaining product quality. By closely monitoring these critical parameters, you can ensure a smooth processing operation while ensuring food safety and quality standards are met.

Addressing Quality Control Issues

Addressing quality control issues is an essential aspect of meat chicken processing day prep. These issues can arise due to various factors such as equipment malfunctions, inadequate training, or contaminated raw materials. To tackle these problems effectively, it’s crucial to conduct a root cause analysis.

This involves identifying the underlying reasons behind the issue and taking corrective action accordingly. For instance, if there’s an increase in spoilage rates, investigate whether it’s due to insufficient chilling time, incorrect storage conditions, or inadequate handling procedures.

Developing a corrective action plan is also vital. This should involve implementing changes to prevent similar issues from arising in the future. It might include retraining staff on proper handling techniques, adjusting production schedules to accommodate increased demand, or replacing outdated equipment with more efficient models.

By addressing quality control issues promptly and effectively, meat chicken processing plants can maintain high standards of safety and quality while minimizing losses due to subpar products or wasted resources.

Post-Processing Steps: Finishing Touches

Now that you’ve eviscerated, gutted, and washed those chickens, it’s time to put them through some final processing steps to get them ready for market. We’ll walk you through the finishing touches needed.

Final Inspection and Packaging

As the chicken processing day nears its end, it’s essential to conduct a thorough final inspection before packaging. This critical step ensures that every bird meets the highest quality standards and is safe for consumption.

Inspectors carefully examine each chicken for visual defects such as bruising, discoloration, or unusual growth patterns. They also check for signs of contamination, including visible stains or residue on the feathers, skin, or internal organs. Any birds found to be unsuitable for human consumption are promptly removed from the production line and sent for further processing, such as rendering.

Inspectors must maintain a keen eye for detail during this process, as even minor imperfections can impact the chicken’s overall quality and value. To streamline this step, some processors employ visual inspection systems that use high-intensity lighting to highlight potential defects. By taking the time to thoroughly inspect each bird, you can minimize waste, reduce the risk of contamination, and maintain a reputation for producing top-quality meat chickens.

Labeling and Branding

Accurate labeling and branding are crucial steps in preparing your product for distribution. As you finalize your chicken processing tasks, it’s essential to ensure that your products bear accurate labels and adhere to your company’s branding guidelines.

When it comes to labeling, start by clearly indicating the type of meat, weight, and any relevant certifications or claims (e.g., organic, free-range). You should also include packaging information such as storage instructions and preparation guidelines. Use a font size that is easy to read and ensure that all text is legible on both labels and packaging materials.

For branding, consider incorporating your company’s logo, color scheme, and tagline consistently across all products. This helps build recognition and reinforces your brand identity. To maintain consistency, develop a style guide outlining acceptable uses for your logo, colors, and typography.

Remember to also check local regulations regarding labeling requirements, such as allergen warnings or country-of-origin labeling. By accurately labeling and branding your chicken products, you’ll not only comply with industry standards but also enhance customer trust and loyalty.

Storage and Shipping Preparation

As you near the end of the processing day, it’s essential to focus on storage and shipping preparation to ensure the quality and safety of your meat chicken products. Start by maintaining a clean and organized workspace, free from debris and cross-contamination.

Proper storage conditions are crucial in preserving the freshness and quality of your products. Store processed meats at a consistent refrigerator temperature of 40°F (4°C) or below. Ensure that packaging is airtight and sealed to prevent moisture buildup and contamination.

Label each product with its contents, weight, and date of processing. This will help you track inventory and maintain accurate records. Consider using color-coding for different product types or categories to streamline identification and organization.

Before shipping, inspect the products for any visible damage or defects. Verify that packaging is secure and meets local regulations. Double-check labeling and documentation to ensure compliance with food safety standards. Proper storage and shipping preparation will help you maintain a high-quality final product and reduce the risk of spoilage or contamination during transportation.

Special Considerations: Food Safety and Regulations

As you continue through the meat chicken processing day prep, it’s crucial to consider food safety regulations and take necessary steps to maintain a safe environment for handling poultry. This involves adherence to specific guidelines and protocols.

Compliance with Food Safety Regulations

Compliance with food safety regulations is paramount when it comes to meat chicken processing. One of the most critical components of this compliance is having a HACCP (Hazard Analysis and Critical Control Points) plan in place. This plan outlines potential hazards, their likelihood of occurrence, and the measures taken to mitigate them at each step of the process.

For example, during the evisceration process, it’s crucial to follow proper sanitation procedures to prevent cross-contamination. The HACCP plan would outline specific steps such as handwashing, sanitizing equipment, and separating raw products from ready-to-eat products. It’s also essential to label allergens accurately. For chicken processing facilities that handle peanuts or tree nuts, this means clearly labeling packaging with allergen warnings.

To ensure compliance, it’s vital to regularly review and update the HACCP plan as processes change or new hazards are identified. Additionally, training employees on food safety protocols is crucial to prevent mistakes and maintain a safe working environment. Regular audits and inspections by regulatory bodies can also help identify areas for improvement. By prioritizing food safety and adhering to regulations, meat chicken processing facilities can minimize the risk of contamination and ensure consumer trust in their products.

Handling and Storage of Raw Materials

When handling and storing raw materials on meat chicken processing day prep, it’s crucial to follow proper procedures to prevent contamination and maintain product quality. Raw materials such as live chickens, feed, and equipment must be handled hygienically to minimize the risk of contamination.

Chickens should be unloaded from transportation containers into a clean, well-ventilated area for further handling. Workers should wear gloves and wash their hands frequently before touching any raw materials. Chickens are then sorted and placed in designated holding areas where they can rest and acclimate before processing.

Raw feed must also be stored in a clean, dry area away from direct sunlight and potential contamination sources. Equipment such as knives, cutting boards, and utensils should be sanitized regularly to prevent cross-contamination of bacteria like Salmonella and Campylobacter.

It’s essential to follow the “First-In-First-Out” (FIFO) principle when storing raw materials to ensure that older materials are processed before newer ones. This helps maintain product quality and reduces the risk of contamination. Regular cleaning and sanitizing of storage areas is also crucial to prevent pest infestations and bacterial growth.

Proper handling and storage procedures will help prevent contamination, maintain product quality, and reduce the risk of recalls or foodborne illnesses. By following these guidelines, you can ensure a smooth meat chicken processing day prep operation that meets regulatory requirements and keeps consumers safe.

Training and Certifications for Meat Chicken Processing

When it comes to meat chicken processing day prep, ensuring that staff are properly trained and certified is crucial for maintaining a safe and compliant environment. According to OSHA guidelines, employees handling poultry must receive annual training on specific tasks and procedures to minimize the risk of contamination.

This training typically covers topics such as hand washing, sanitation, and proper equipment usage. For instance, workers must learn how to operate the eviscerator machine safely and efficiently to avoid cross-contamination of poultry parts. They also need to be aware of personal protective equipment (PPE) requirements, including gloves and masks, to prevent exposure to potential allergens.

To stay compliant with OSHA regulations, meat chicken processing facilities should maintain accurate records of employee training and certifications. This includes documentation of initial training sessions, refresher courses, and annual certification renewals. By prioritizing staff education and certification, facilities can reduce the risk of foodborne illnesses and ensure a smooth day prep operation.

Frequently Asked Questions

What are the most common mistakes to avoid during meat chicken processing day prep?

When it comes to pre-processing day prep, one of the most critical mistakes is neglecting food safety and quality control protocols. This can lead to contamination, spoilage, or even regulatory issues. To avoid this, ensure that all equipment is properly sanitized, supplies are organized, and a regular cleaning schedule is maintained.

How often should I perform deep cleaning and sanitation procedures during meat chicken processing?

Regular deep cleaning and sanitation procedures should be performed at the beginning of each production day to prevent cross-contamination and maintain food safety. This includes tasks such as cleaning equipment, disinfecting workstations, and sanitizing packaging materials.

What are some essential tools or equipment I need to invest in for efficient meat chicken processing?

Investing in high-quality equipment that meets regulatory requirements is crucial for efficient meat chicken processing. Some essential tools include a deboning machine, trimming saw, and temperature control system. Additionally, consider investing in ergonomic workstations and safety gear to improve productivity and prevent accidents.

Can I use recycled or reused packaging materials during meat chicken processing?

While it’s tempting to reduce waste by reusing packaging materials, using recycled or reused materials can compromise food safety and quality control. Instead, opt for new, high-quality packaging materials that meet regulatory requirements and are specifically designed for meat chicken processing.

What are some common challenges I might face when implementing a new sanitation and cleaning schedule during meat chicken processing?

Implementing a new sanitation and cleaning schedule can be challenging, especially if it requires significant changes to your current workflow or equipment setup. To overcome this, start by identifying key areas for improvement and prioritizing tasks based on risk and urgency. Additionally, consider training staff on new procedures and providing clear guidelines for maintaining food safety and quality control throughout the processing operation.