If you’re a poultry farmer, you know how vulnerable your birds can be to predators. Foxes, coyotes, and stray dogs are just a few of the threats that can leave you with a devastating loss. Electric netting is a popular solution for protecting your flock from these dangers. Not only does it effectively deter predators, but it’s also customizable to fit your specific needs. But with so many options available, choosing the right electric netting system for your farm can be overwhelming.

In this article, we’ll break down the benefits of using electric netting for poultry protection and provide guidance on how to choose the perfect system for your farm. We’ll cover everything from understanding the basics of electric netting to exploring customization options and predator deterrence strategies. By the end of this post, you’ll have a clear understanding of how electric netting can help safeguard your flock and increase productivity on your farm.

Benefits and Advantages of Electric Netting

Electric netting offers several advantages over traditional fencing methods, providing a safe and effective way to protect your poultry from predators. Let’s explore these benefits together in this section.

Improved Predator Protection

When it comes to protecting your poultry from predators, electric netting is an effective and reliable solution. One of the most significant benefits of using electric netting is its ability to deter coyotes, foxes, and raccoons – some of the most common threats to backyard flocks.

Electric netting works by delivering a mild shock to predators who come into contact with it, which is uncomfortable but not painful for humans. This shock is enough to deter even the most persistent predators from attempting to breach the fence. For example, a study conducted by the University of Wisconsin found that electric fencing reduced coyote attacks on poultry flocks by 90%.

To set up an effective predator protection system using electric netting, it’s essential to consider the following factors: height, mesh size, and tension. Aim for a minimum height of 3 feet above the ground to prevent digging predators from burrowing under the fence. Use a mesh size of at least 4 inches to prevent predators from reaching through with their claws or teeth. Finally, ensure the netting is tightly stretched to prevent sagging, which can create weak points in the system.

By following these guidelines and choosing the right electric netting for your flock, you can enjoy peace of mind knowing that your poultry are safe from predators.

Increased Safety for Farmers and Handlers

One of the significant advantages of electric netting for poultry is its ability to ensure increased safety for farmers and handlers. Unlike traditional fencing methods that can be hazardous when handling wires or other materials, electric netting eliminates this risk entirely.

The safety features built into electric netting are designed with users in mind. The fencing system uses a low-impedance circuitry that allows the current to flow freely around the animal’s body, reducing the shock experienced by humans if they were to touch the fence. This feature significantly minimizes the risk of injury or even death.

Farmers and handlers who have transitioned to electric netting for their poultry operations report a significant decrease in near-miss incidents. By choosing an electric netting system that is designed with safety features, you can enjoy peace of mind while working around your flock. Always ensure that the netting is properly maintained, cleaned, and inspected regularly to prevent any potential issues.

Customization and Flexibility

When it comes to electric netting for poultry, one of the biggest advantages is its ability to be customized and flexible. This means that whether you have a small backyard flock or a large commercial operation, there’s an electric netting system that can fit your specific needs.

One of the key benefits of customization is that it allows you to protect your birds from predators in areas where traditional fencing methods wouldn’t work. For example, if you have a wooded area on your farm with steep slopes and rocky terrain, a standard fence would be difficult to install. But electric netting can be easily stretched across these areas, creating a secure perimeter for your birds.

Another advantage of customization is that it allows you to create specific enclosures for different types of poultry. For instance, if you have chickens that are prone to flying, you can set up an enclosure with higher netting to keep them contained. Or, if you’re raising turkeys or geese, you can use taller netting to protect them from aerial predators.

By choosing a customizable electric netting system, you can create a safe and secure environment for your poultry that meets their specific needs.

Types of Electric Netting for Poultry

When choosing electric netting for your poultry, you need to consider several types that cater to different needs and situations. This includes considerations for small backyard flocks versus larger commercial farms.

High-Tensile Wire vs. Perimeter Netting

When it comes to choosing electric netting for your poultry farm, you’ll likely come across two popular options: high-tensile wire and perimeter netting. Both have their advantages and disadvantages, which we’ll break down below.

High-tensile wire is a cost-effective option that’s ideal for larger farms or those with complex layouts. It’s durable, easy to install, and can withstand harsh weather conditions. However, it may require more maintenance than other options, as loose wires need to be tightened regularly. Additionally, high-tensile wire can be less effective at keeping out larger predators like bears or wolves.

Perimeter netting, on the other hand, is a great choice for smaller farms or those with a simpler layout. It’s lightweight and easy to install, making it perfect for hobby farmers or those new to electric netting. However, perimeter netting may not be as effective at keeping out persistent predators, and can be more prone to damage from weather or animal impact.

Ultimately, the choice between high-tensile wire and perimeter netting will depend on your specific farm needs and layout. Consider factors like farm size, terrain, and predator threats when making your decision. Be sure to install your electric netting carefully, following the manufacturer’s instructions to ensure maximum effectiveness and safety for both your poultry and yourself.

Portable and Permanent Solutions

When it comes to electric netting for poultry, you have two main options: portable and permanent solutions. Each type has its own set of benefits and drawbacks that can impact the overall effectiveness and efficiency of your setup.

Portable electric netting is ideal for farmers with smaller flocks or those who need to rotate their birds regularly. These nets are lightweight, easy to install, and can be moved from one area to another as needed. However, they may not provide the same level of protection as permanent solutions, especially in areas prone to extreme weather conditions.

Permanent electric netting, on the other hand, is a more long-term investment that provides continuous protection for your flock. These nets are often more robust and durable than their portable counterparts, making them an excellent choice for large-scale operations or those with limited space. However, they can be more expensive upfront and may require more labor to install.

Ultimately, the choice between portable and permanent electric netting comes down to your specific needs and resources. Consider factors such as flock size, terrain, and budget when deciding which solution is best for you.

Installation and Maintenance

When it comes to setting up electric netting for your poultry, proper installation is key to ensuring both safety and effectiveness. In this section, we’ll walk you through the essential steps.

Preparing the Area for Installation

Before you start installing electric netting for your poultry, it’s crucial to prepare the area where the netting will be placed. This involves clearing debris and creating a safe working environment to ensure that the installation process goes smoothly.

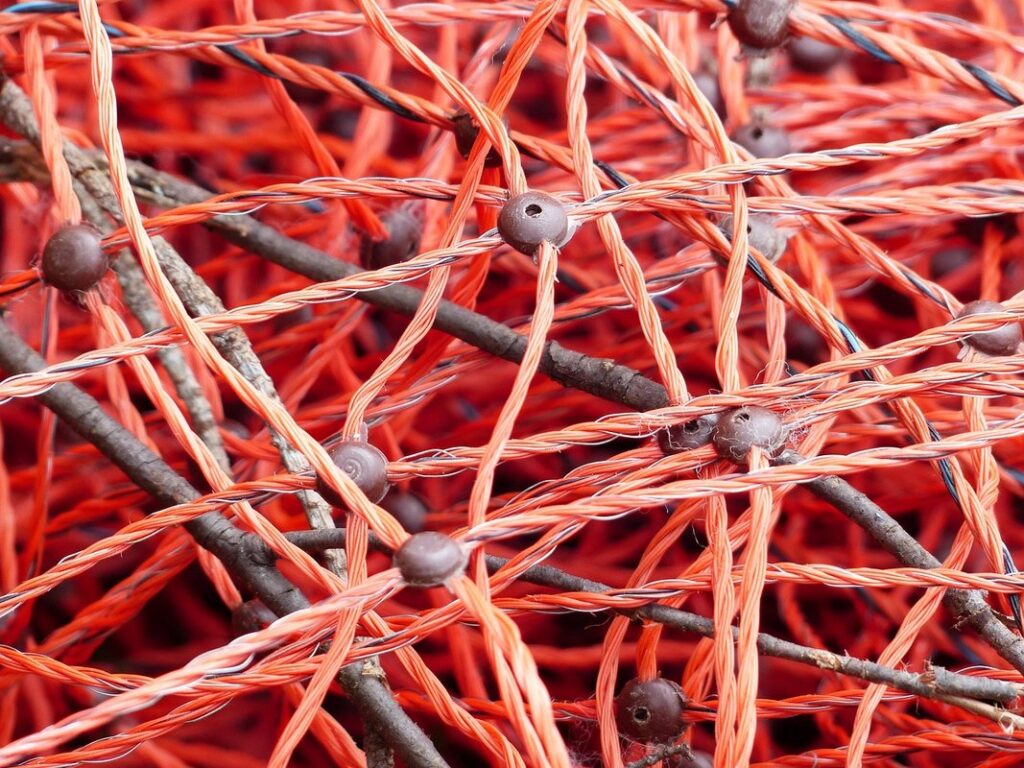

Begin by inspecting the site where you plan to install the netting. Check for any rocks, twigs, or other objects that could interfere with the netting’s performance or damage it during use. Remove any debris and clear a path wide enough for you to comfortably move around while installing the netting. You should also check for any holes or dips in the ground that could cause the netting to sag or come into contact with vegetation, which can compromise its effectiveness.

Make sure the area is free from power lines, overhead obstacles, and other hazards that could pose a risk during installation or to your poultry when they’re roaming under the netting. A well-prepared site will not only ensure the success of your electric netting installation but also provide a safe environment for your birds to thrive in.

Installing Electric Netting Safely

When installing electric netting safely and efficiently, it’s essential to follow these crucial steps. First, carefully read the manufacturer’s instructions for specific guidance on setting up the system.

Start by choosing a flat area with minimal obstacles, such as trees or rocks, that could interfere with the netting. Mark out the perimeter of your enclosure using stakes and twine to create a clear boundary.

Next, set up corner posts, which are usually provided with the kit, and secure them firmly into the ground using long screws or anchors. These will serve as anchor points for the wires or nets. Always ensure that the posts are spaced at least 5-6 feet apart to maintain optimal voltage distribution.

Now, thread the wires or netting through the corner post’s gate and begin attaching it to the posts in a smooth, continuous motion. Use clips, ties, or specialized netting clamps to secure the netting firmly in place, making sure not to leave any loose ends that could compromise the system’s safety.

Always maintain a safe distance from the energized net when installing, as touching the wires can result in serious injury or even death.

Choosing the Right Electric Netting System

When selecting an electric netting system for your poultry, you’ll want to consider factors such as terrain difficulty, animal size, and ease of use to ensure a safe and secure setup.

Factors to Consider When Selecting a System

When choosing an electric netting system for your poultry, several key factors come into play. First and foremost, consider the size of your farm. A larger property will require more extensive coverage, which may necessitate a higher-powered or longer-lasting system. Conversely, smaller farms can often get away with simpler, less expensive options.

Predator threats are another crucial consideration. If you live in an area prone to coyotes, foxes, or other predators that target poultry, you’ll need a more robust system capable of deterring these threats. A higher voltage setting or added features like motion sensors may be necessary to keep your flock safe.

Budget is also a vital aspect to consider. While a premium electric netting system can provide unparalleled protection and convenience, it’s essential to balance cost with your farm’s specific needs. Be sure to factor in the long-term benefits of investing in a high-quality system that will save you money on replacement costs and reduced stress over time.

Brand Comparison and Reviews

When it comes to selecting an electric netting system for your poultry, choosing the right brand can be overwhelming. With numerous options available, each with its unique features and pricing, making an informed decision requires some research.

Some popular brands in the market are Perimeter Protection Systems (PPS), Suwannee Valley Farms (SVF), and Net Result. PPS offers durable nets with a 5-year warranty and is known for its affordability, with prices starting at around $2 per foot. On the other hand, SVF provides high-quality nets made from heavy-duty polypropylene with a 10-year warranty, but comes with a higher price tag of about $3.50 per foot.

Net Result, another well-known brand, offers customization options and a 5-year warranty at a competitive price of around $2.75 per foot. While these brands have their own strengths, customer reviews often serve as the deciding factor for many users. Be sure to read reviews from multiple sources to get an accurate understanding of each brand’s performance in real-world settings.

When evaluating these options, consider factors such as durability, warranty length, and price point to make a decision that best suits your needs.

Electric Netting for Different Types of Poultry

Whether you’re raising chickens, turkeys, or ducks, we’ll walk you through how to choose the right electric netting for each type of poultry, keeping them safe and secure.

Small-Scale Chicken Keeping

If you’re a small-scale chicken keeper, electric netting is an excellent choice for your flock’s protection. Not only is it portable and easy to set up, but it also provides a safe and secure way to keep predators at bay. One of the biggest advantages of using electric netting for backyard chickens is its flexibility – you can easily move it around to accommodate changing pasture conditions or to protect different areas of your yard.

For example, you can use electric netting to enclose a small section of your garden where you’re growing vegetables that might be attractive to birds. This not only protects your crops but also keeps your chickens from getting into trouble by preventing them from pecking at plants they shouldn’t be eating. Plus, with electric netting, you don’t have to worry about building permanent fencing structures or dealing with tangled wires.

When setting up electric netting for your backyard chicken flock, make sure to follow the manufacturer’s instructions and take necessary safety precautions. This includes ensuring that the netting is securely staked down and that all wires are properly insulated to prevent damage or shock.

Large-Scale Duck or Turkey Operations

When it comes to large-scale duck or turkey operations, electric netting can be a game-changer. Not only does it provide an efficient way to protect these birds from predators, but it also simplifies the process of moving animals between pastures and reducing labor costs.

One of the primary advantages of using electric netting in commercial settings is its ability to contain large groups of animals without sacrificing their freedom to roam. This is particularly important for ducks and turkeys, which require regular movement to stay healthy and happy. Electric netting allows farmers to create a safe and enclosed area that can be easily moved as needed, making it easier to rotate pastures and reduce the risk of disease.

However, there are some challenges to consider when using electric netting on a large scale. For example, you’ll need to ensure that your fencing is properly maintained and inspected regularly to prevent damage or malfunction. Additionally, you may need to invest in additional infrastructure such as energizers and grounding systems to support the fencing. Despite these considerations, electric netting can be a cost-effective and efficient solution for commercial poultry operations.

Troubleshooting Common Issues

If you’re experiencing issues with your electric netting, don’t worry – we’ve got you covered. This section will walk you through common problems and provide simple solutions to get your poultry safely contained again.

Common Problems and Solutions

One of the most frustrating things that can happen when using electric netting for poultry is a short circuit or faulty wiring. If you notice that the netting has stopped working or the voltage reading is significantly lower than expected, it’s likely due to a problem with the electrical system.

Before troubleshooting, make sure to turn off the energizer and inspect the netting carefully. Check for any signs of damage, such as frayed wires, worn-out posts, or cuts in the netting material. Replace any damaged components immediately to prevent further problems.

Common causes of short circuits include loose connections, corrosion on metal components, or poor installation techniques. To fix a short circuit, follow these steps: check and tighten all connections, replace corroded parts with new ones, and inspect the netting for any signs of wear or damage. Regularly inspecting and maintaining your electric netting system can help prevent these issues from arising in the first place.

If you’re unsure about how to fix a problem or if it’s beyond your expertise, consult the manufacturer’s instructions or contact their support team for assistance.

Repairing and Replacing Electric Netting Components

When it comes to maintaining an electric netting system for poultry, repairing and replacing worn-out or damaged components is essential to ensure its effectiveness. Over time, the netting may become frayed, the wires can break, or the posts may become bent, compromising the fence’s integrity.

To identify worn-out areas, inspect your electric netting regularly, looking for signs of damage such as cuts, holes, or excessive wear. Check for broken wires by gently tugging on them; if they snap easily, it’s time to replace them. Bent posts can be straightened using a post mender tool or replaced altogether.

To repair frayed netting, you’ll need some basic materials like wire cutters, pliers, and electrical tape. Cut the damaged section of netting, then use the pliers to strip the insulation from the remaining wires. Twist the exposed ends together securely and cover with electrical tape. When replacing broken posts or wires, follow the manufacturer’s guidelines for specific instructions.

Regular maintenance will help prevent costly repairs down the line.

Frequently Asked Questions

What are the most common electric netting installation mistakes to avoid?

Installing electric netting requires careful planning and execution to ensure its effectiveness and longevity. Common mistakes include inadequate terrain assessment, insufficient wire tension, and poor post placement. To avoid these errors, carefully assess your farm’s topography, follow the manufacturer’s guidelines for wire tension and post spacing, and consult with a professional if needed.

Can electric netting be used in areas with high wind or harsh weather conditions?

Yes, electric netting can be effective in windy or rainy areas, but it requires additional measures to ensure its stability. Consider using reinforced posts, weighting the netting down with sandbags or weights, and securing the netting with guy wires to prevent damage.

How do I choose the right electric netting system for my specific farm needs?

Choosing the right electric netting system involves considering factors like terrain difficulty, predator types, and fencing purpose. Consider the size of your flock, type of predators in your area, and your farm’s unique conditions when selecting a system. Consult with experts or manufacturers to ensure you’re choosing the most suitable solution.

What is the maintenance schedule for electric netting systems?

Regular maintenance is crucial to ensure electric netting remains effective and lasts long. Check the fence posts and netting regularly for damage or wear, inspect wire tension, and perform routine cleaning to prevent corrosion. Follow the manufacturer’s recommended maintenance schedule and address any issues promptly.

Can I use electric netting in conjunction with other fencing methods?

Yes, electric netting can be combined with other types of fencing, such as high-tensile wire or perimeter netting, to create a multi-layered protection system. This approach can enhance predator deterrence and improve overall farm security. Consult with experts or manufacturers to determine the best combination for your specific needs.