If you’re a poultry farmer looking to improve your pasture management, reduce parasite infestations, and enhance animal health, you’re in luck. Electric netting for poultry rotation is a game-changer. This simple yet effective solution has gained popularity among farmers who want to provide their birds with the best possible living conditions while also protecting themselves from unwanted visitors – like predators. By using electric netting, you can rotate your flock through different pastures, allowing them to feed on fresh grass and reducing the risk of parasite infestations that come with overcrowded conditions. In this article, we’ll explore how electric netting works, its benefits for poultry rotation systems, and provide tips on how to get started with implementing it on your farm.

Introduction to Electric Netting

Electric netting is a flexible and efficient way to protect your poultry from predators, and we’re excited to dive into the basics of how it works. In this section, we’ll cover the fundamentals of electric netting for poultry rotation.

Benefits of Electric Netting for Poultry

When it comes to managing pasture for poultry rotation, electric netting offers numerous benefits that can improve overall farm efficiency and animal health. One of the primary advantages of using electric netting is its ability to enhance pasture management. By temporarily fencing off areas of pasture, you can rotate your birds through different sections, allowing each area to recover and replenish. This not only prevents overgrazing but also encourages healthy vegetation growth.

Electric netting also plays a crucial role in reducing parasite infestations among poultry. These pesky critters often thrive on contaminated soil and grass, putting the health of your birds at risk. By moving your flock regularly through clean areas, you significantly minimize their exposure to parasites. This is especially important for young or immunocompromised birds that are more susceptible to these afflictions.

In addition to improved pasture management and reduced parasite infestations, electric netting can also contribute to enhanced animal health overall. When birds have access to fresh, untainted pastures, they’re more likely to remain disease-free. Regular rotation with the help of electric netting ensures that your poultry always has a clean slate to forage on, resulting in healthier and happier birds.

Understanding Electric Netting Systems

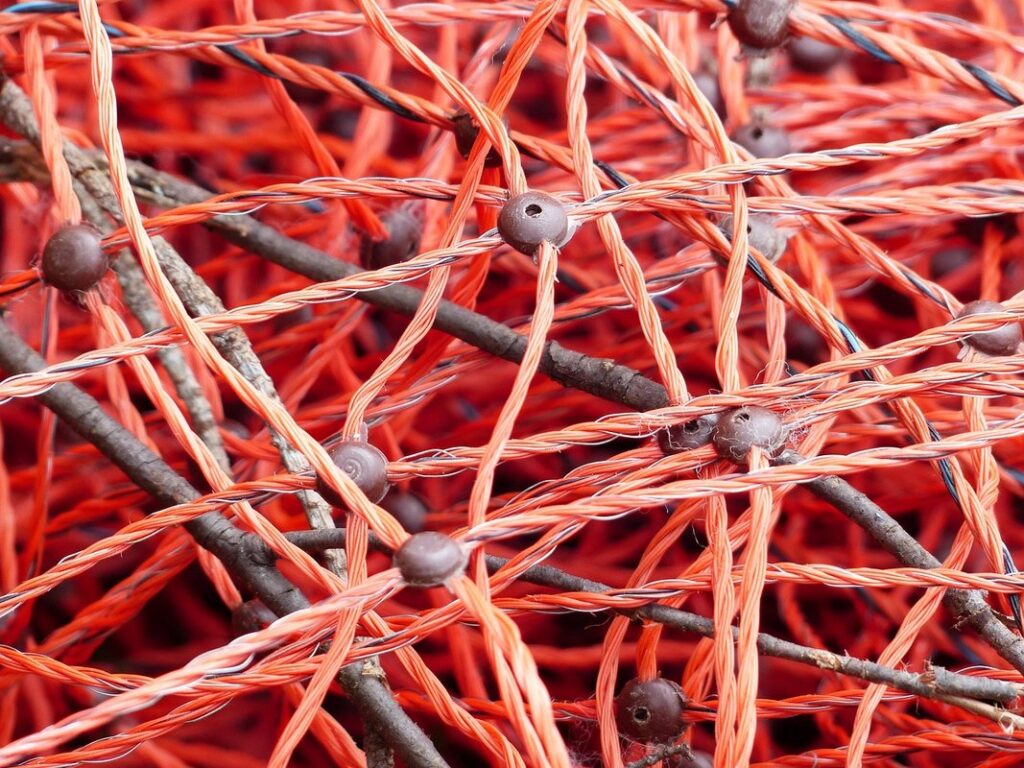

When it comes to electric netting systems, there are several types available to suit different farm sizes and poultry rotation needs. The most common components of an electric netting system include energizers, conductors (such as polytape or polywire), and the netting itself.

The energizer is the heart of the system, providing a low voltage current that flows through the conductor and into the netting. This creates an invisible barrier around your poultry that deters predators such as coyotes, foxes, and stray dogs. The voltage is typically set between 2-7 milliamps, depending on the system’s specifications.

It’s essential to choose a suitable energizer for your farm size and the number of animals you’re rotating through the pasture. Consider factors like power source (battery or solar), portability, and ease of use when selecting an energizer. For example, if you have a large farm with multiple pastures, a solar-powered energizer may be more cost-effective in the long run.

When setting up your electric netting system, ensure that all connections are secure and the voltage is adjusted according to the manufacturer’s guidelines. Regularly inspect the system for damage or wear, replacing any compromised components promptly to maintain its effectiveness.

Planning a Successful Poultry Rotation with Electric Netting

To ensure your poultry rotation is smooth and successful, we’ll explore the key steps to plan and implement electric netting for rotational grazing. This includes choosing the right size and layout.

Assessing Your Farm’s Needs and Goals

Before you start setting up electric netting on your farm, it’s essential to assess your specific needs and goals. This will help you create a poultry rotation plan that meets the unique demands of your land, climate, and flock size.

Consider your land availability – do you have enough space to accommodate multiple paddocks or grazing areas? Electric netting allows for flexible fencing solutions, but you’ll want to ensure you have sufficient acreage to rotate your birds without overcrowding. Climate is also a crucial factor; if you live in an area with extreme temperatures, you may need to adjust your rotation schedule accordingly.

Think about the size of your flock and their specific needs. Larger flocks require more land to graze, while smaller groups might thrive on smaller paddocks. Assessing these factors will help you determine the optimal configuration for your electric netting system, ensuring a successful poultry rotation that meets your birds’ needs and maximizes productivity.

Choosing the Right Electric Netting for Your Operation

When choosing an electric netting system for your poultry operation, there are several key considerations to keep in mind. First and foremost, think about the type of material you need: polywire or polytape? Polywire is often a good choice for smaller operations or those on a budget, as it’s lightweight and easy to handle. However, it may not provide the same level of durability as polytape, which can withstand harsh weather conditions and heavy use.

Next, consider the voltage level you need. Higher voltage settings (typically 4-7kV) are best suited for larger operations or those with high predator pressure, while lower voltage settings (typically 2-3kV) may be sufficient for smaller farms or areas with minimal predation. Another important factor is fencing design: will your netting need to conform to specific shapes or corners? Make sure to select a system that allows for easy installation and adjustment.

It’s also essential to consider the quality of the electric netting, including its gauge (thickness) and strand count. A higher gauge and more strands will provide greater durability and predator protection.

Installing Electric Netting for Poultry Rotation

When it comes to implementing a poultry rotation system, installing electric netting is a crucial step that requires attention to detail and careful planning. Let’s walk through the process together, step by step.

Preparing the Land and Fencing

Before installing electric netting for poultry rotation, it’s essential to prepare the land and set up the fencing. This involves clearing the area of debris, removing any existing obstacles, and grading the ground to ensure even terrain. You’ll also need to determine the layout of your electric netting system, taking into account the size of your pasture and the movement patterns of your birds.

To begin setting posts for the electric netting, start by marking the perimeter of your area with stakes and twine. Then, use a post-hole digger or a power auger to create holes for each post, about 12-18 inches deep and 24-36 inches apart. Fill the holes with concrete to secure the posts in place.

Next, stretch the conductors (the electric wires) between the posts, making sure they’re tight and evenly spaced. Connect the conductors to an energizer, which will supply the necessary voltage for the netting system. Finally, attach the electric netting to the posts using clips or ties, ensuring a snug fit around any obstacles.

When installing your electric netting, remember to follow local building codes and safety guidelines to avoid electrical shock hazards.

Connecting the Energizer and Testing the System

Once you’ve installed your electric netting around the pasture, it’s essential to connect the energizer and test the system. This will ensure that the shock from the net is strong enough to deter predators.

Start by locating the energizer and identifying the correct connections for the netting. Typically, these are color-coded wires or labeled terminals. Consult your manual or manufacturer’s instructions if you’re unsure about the specific configuration. Next, connect the netting to the energizer using the corresponding wires. Make sure to secure any loose connections with electrical tape to prevent accidental disconnections.

Now it’s time to test the system. Turn on the energizer and walk along the perimeter of the netting while holding a metal object like a screwdriver or stick. If you feel a strong, but not painful, shock when touching the net, the system is working effectively. Repeat this process several times to ensure consistency. Remember that regular testing will also help maintain optimal voltage levels throughout your pasture.

Managing Poultry Health with Electric Netting

To keep your flock healthy and thriving, electric netting offers a simple yet effective solution for managing poultry health through rotational grazing practices. This approach can greatly reduce disease transmission among birds.

Reducing Parasite Infestations

Using electric netting as part of your poultry rotation strategy can significantly reduce parasite infestations. This is achieved by physically keeping birds away from contaminated areas where parasites are most likely to be present. By doing so, you minimize their exposure to disease-carrying insects such as ticks and flies that thrive in these environments.

Electric netting not only prevents parasite infestation but also helps control mite populations that thrive on the droppings of your flock. Mites, for instance, can cause anemia and weight loss among poultry. By containing these parasites within a designated area, you reduce the risk of them spreading to other parts of the farm.

To maximize the effectiveness of electric netting in controlling parasite infestations, ensure that it is properly installed around areas with high levels of contamination. Consider the movement patterns of your birds and set up the fencing accordingly to prevent them from getting into areas they shouldn’t be in. Regular inspection and maintenance of the netting will also help keep parasites at bay.

Electric netting can also serve as a preventive measure against diseases spread by parasites such as Histomoniasis or coccidiosis which are common among poultry.

Improving Flock Performance and Growth

When you use electric netting for poultry rotation, you can expect to see significant improvements in flock performance and growth. One of the most notable benefits is reduced stress on the birds. Electric netting allows you to move them to fresh pasture without exposing them to predators or harsh weather conditions. This translates into healthier birds that are more productive.

In fact, studies have shown that flocks rotated using electric netting can experience improved feed conversion rates. This means they require less food to produce the same amount of eggs or meat. For example, a study on egg-laying hens found that those rotated through electric netting required 10% less feed than stationary birds.

Electric netting also has a positive impact on egg production. By allowing your flock access to fresh pasture and reducing stress, you can expect to see an increase in egg production. In some cases, this can be as high as 20-30 eggs per year more than stationary flocks. To maximize these benefits, it’s essential to rotate your flock regularly and provide them with adequate feed and water at all times.

Troubleshooting Common Issues with Electric Netting

Don’t let a malfunctioning net get in the way of your poultry rotation plan, so we’ll tackle common issues and provide solutions to keep your birds safe and secure. From faulty posts to frayed wires, we’ve got you covered.

Identifying and Addressing Voltage Problems

When it comes to ensuring the effectiveness of electric netting for poultry rotation, voltage problems can be a major concern. Identifying and addressing these issues promptly is crucial to prevent predator deterrence from being compromised.

To identify voltage problems, check the netting’s voltage meter regularly, ideally at dawn and dusk when predators are most active. If you notice any fluctuations or drops in voltage, investigate immediately. Common causes of voltage loss include worn-out posts, faulty insulators, or damaged netting.

Troubleshooting voltage issues often requires a combination of observation and repair work. Check the net for signs of wear and tear, such as frayed wires or holes. Ensure that all posts are securely anchored to prevent sagging, which can reduce voltage levels. Additionally, verify that the electric fence tester is calibrated correctly and functioning properly.

Regular maintenance of optimal voltage levels can be achieved by replacing worn-out parts promptly and ensuring that all connections are secure.

Managing Overgrazing and Pasture Quality

When using electric netting for poultry rotation, overgrazing and pasture quality can become significant concerns. Overgrazed pastures not only impact the health of your birds but also affect the overall ecosystem. To manage overgrazing effectively, consider implementing a rotational grazing plan.

Here are some key strategies to maintain high-quality pastures:

* Monitor grass growth: Regularly inspect your pastures and remove netting when grass reaches an optimal height for grazing (typically 6-8 inches). This ensures birds don’t consume too much of the same pasture, allowing it to recover.

* Increase netting size: Gradually increase the area of electric netting as the pasture recovers. This allows you to make the most of your land while preventing overgrazing.

* Introduce cover crops: Planting cover crops between rotations helps to replenish nutrients in the soil and maintain biodiversity, supporting a healthier ecosystem.

By implementing these strategies, you can maintain high-quality pastures and promote sustainable poultry rotation.

Conclusion: Maximizing the Benefits of Electric Netting for Poultry Rotation

To maximize the benefits of electric netting for poultry rotation, it’s essential to remember that this system is only as effective as its execution. Make sure to thoroughly inspect your fencing before introducing birds, and regularly check for any signs of damage or wear. With proper maintenance and regular checks, you can rest assured that your flock will remain safe and secure.

By implementing electric netting in conjunction with other rotational grazing strategies, you’ll be able to promote healthy soil fertility and reduce the risk of disease transmission among your birds. Furthermore, this system allows for more efficient use of space, enabling you to manage larger flocks on smaller plots.

Frequently Asked Questions

Can I use electric netting for poultry rotation on slopes or uneven terrain?

Yes, electric netting can be adapted to fit various terrain types, including slopes and uneven areas. When installing on sloping land, ensure the netting is securely attached and adjusted for optimal voltage delivery. This might require using specialized anchoring systems or additional support structures.

How do I prevent birds from getting too accustomed to the electric netting?

To maintain the effectiveness of electric netting, it’s essential to rotate your flock regularly through different pastures and adjust the netting’s placement periodically. This prevents birds from becoming desensitized to the shock. Additionally, ensure the energizer is set at a suitable voltage for your operation.

What are some common mistakes to avoid when installing electric netting?

When setting up electric netting for poultry rotation, it’s crucial to avoid low-hanging branches and obstacles that could interfere with the netting or energizer. Also, ensure you follow proper grounding procedures to prevent electrical shocks during installation.

Can I use electric netting for protecting smaller birds like quail or turkeys?

Electric netting can be effective for protecting a variety of poultry species, including smaller birds like quail and turkeys. However, the type and size of the netting may need to be adjusted based on the bird’s size and behavior.

How often should I inspect and maintain my electric netting system?

Regular maintenance is key to keeping your electric netting system effective and safe for both your birds and yourself. Inspect the netting at least monthly, checking for any damage or wear that could compromise its integrity. Also, ensure the energizer’s batteries are maintained according to the manufacturer’s instructions.

What should I do if a bird gets caught in the electric netting?

If a bird becomes entangled in the netting, carefully and humanely remove it using proper techniques to avoid injury to yourself or further stress to the animal. Regularly inspecting your flock for signs of entanglement can help prevent such incidents.

How long does an electric netting system typically last before needing replacement?

The lifespan of an electric netting system depends on several factors, including usage frequency, environmental conditions, and maintenance quality. Generally, a well-maintained system can last 2-5 years or longer, although some components may need to be replaced more frequently.

Are there any specific regulations I should be aware of when using electric netting for poultry rotation?

Yes, it’s essential to familiarize yourself with local regulations and ordinances regarding the use of electric fencing on your farm. These can vary by jurisdiction and may pertain to matters such as fencing height, energizer placement, or animal welfare standards.

Can I integrate electric netting into existing fences or paddocks?

While electric netting is designed for flexibility in installation, integrating it with existing fences or paddocks requires careful planning. This might involve reconfiguring your existing infrastructure or adding new components to ensure the system functions as intended and maintains its effectiveness over time.