Are you considering setting up an electric netting system for your backyard flock? Perhaps you’re looking to expand your farm or homestead, but aren’t sure where to start. Choosing the right poultry electric netting system can be a daunting task, especially if you’re new to raising chickens or other birds.

A well-designed and properly installed electric netting system is crucial for keeping predators out and your flock safe. But with so many options available, how do you choose the best one? In this article, we’ll walk you through everything you need to know about setting up a poultry electric netting system, from choosing the right size and type of netting to planning and installing it safely and effectively.

Choosing the Right Electric Netting System

When it comes to selecting an electric netting system for your poultry setup, there are several factors to consider before making a decision. Let’s break down the key considerations.

Understanding Your Farm’s Needs and Goals

When setting up an electric netting system for poultry, it’s essential to start by understanding your farm’s specific needs and goals. This will help you determine the right type of system to choose and ensure its effectiveness.

To begin with, consider why you’re using electric netting in the first place. Is it to keep predators out, such as coyotes or foxes, that are a threat to your flock? Or is it for containment purposes, like keeping birds from escaping or getting into areas they shouldn’t be in? Knowing the purpose will help you narrow down your options.

Next, think about your farm’s layout and terrain. Is it flat and open or hilly and wooded? How much land do you need to cover with electric netting? These factors can impact the type of system you choose and its overall efficiency. For example, if you have a large area with uneven terrain, a more robust system with multiple strands may be necessary.

When selecting an electric netting system, also consider the type of animals you’re protecting. Different systems may be better suited for specific breeds or sizes of birds.

Researching Different Types of Electric Netting Systems

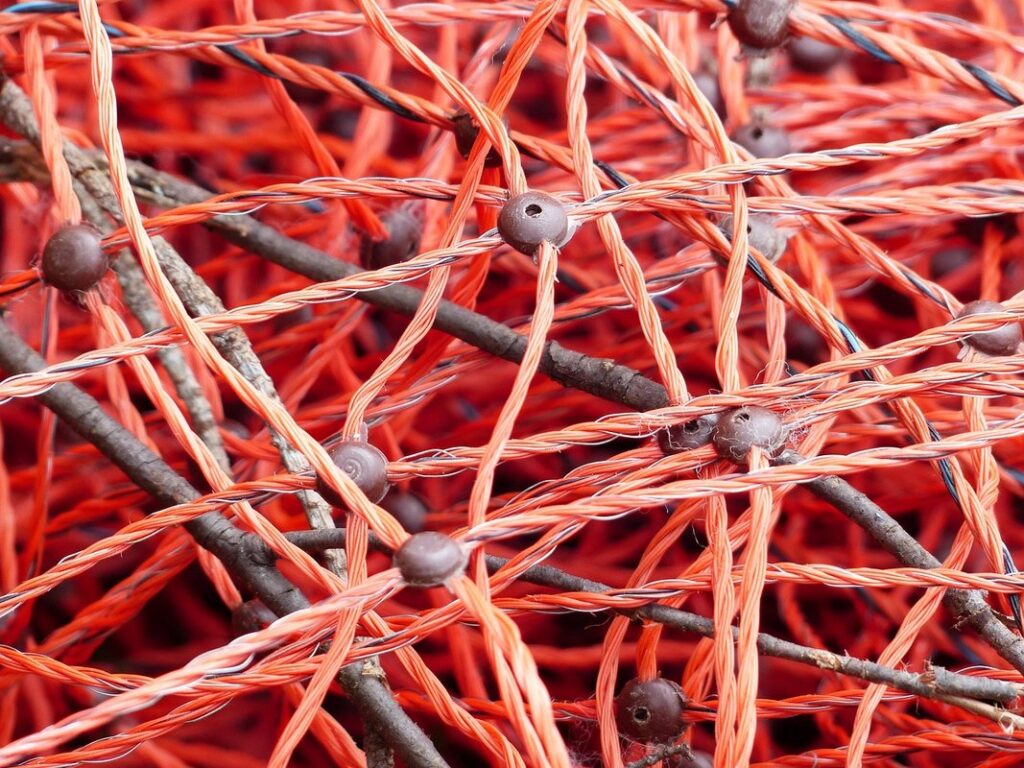

When it comes to electric netting systems for poultry, you’ll find a variety of options available. Each type has its unique features, advantages, and disadvantages that can impact the effectiveness and durability of your setup.

Single-strand electric netting is one of the most common types, utilizing a single wire strand as the energized conductor. This system is often less expensive than multi-strand systems but may require more frequent maintenance to ensure optimal performance. For example, if you’re only containing chickens in a small area with minimal predator pressure, a single-strand system might be sufficient.

Multi-strand electric netting, on the other hand, consists of multiple wire strands that provide enhanced protection against predators and harsh weather conditions. This type is ideal for larger areas or when dealing with more aggressive wildlife. However, multi-strand systems are generally pricier than their single-strand counterparts and may be heavier to handle.

In terms of materials, plastic-coated electric netting offers excellent resistance to rust and corrosion but might not provide the same level of conductivity as metal-coated options. Metal-coated netting, while more durable in extreme weather conditions, can be prone to oxidation over time. Consider your specific needs and environment when deciding between these material types.

When selecting an electric netting system, weigh the pros and cons of each type based on your specific situation. This will help you choose the most suitable option for containing your poultry safely and efficiently.

Factors to Consider When Selecting Electric Netting

When selecting an electric netting system for your poultry setup, there are several key factors to consider. First and foremost, think about the type of animals you’re protecting – different species have unique needs when it comes to fencing. For example, if you’re raising chickens, a 3-4 foot high fence will suffice, but if you’re handling larger birds like turkeys or geese, you’ll need to go up to 5 feet high.

The terrain and layout of your farm also play a significant role in choosing the right electric netting system. Hills, valleys, and uneven ground can make it difficult to deploy and maintain fencing, so consider a system that’s designed for versatility and ease of installation. Additionally, local regulations may dictate specific requirements for fencing around poultry, such as minimum mesh size or height.

Don’t forget to factor in the climate where you live – extreme weather conditions like high winds, heavy snowfall, or scorching heat can affect the durability and performance of your electric netting system. Be sure to choose a system that’s designed to withstand these challenges and is made with durable materials that won’t degrade over time.

Planning and Installing Your Electric Netting System

When setting up your electric netting system, planning is crucial to ensure a safe and effective enclosure for your poultry. In this next step, we’ll walk you through the essential considerations to keep in mind.

Assessing Your Farm’s Terrain and Layout

When assessing your farm’s terrain and layout, it’s essential to consider the slope and elevation of your land. A slight incline may not be a significant issue, but extreme slopes can cause the electric netting to sag or even collapse under its own weight. Take note of any areas with steep drop-offs or uneven terrain, as these will require extra support or modifications.

Additionally, identify any obstacles on your property that could interfere with the installation or effectiveness of your electric netting system. This includes trees, rock formations, and other features that may necessitate adjustments to the layout or additional measures for stability. Consider mapping out your farm’s topography to visualize these factors and plan accordingly.

When evaluating elevation changes, take into account both vertical and horizontal distance. Ensure that the electric netting system is installed at a safe height above any potential escape routes or areas where animals may become trapped. By carefully assessing your terrain and layout, you’ll be able to position your electric netting system for optimal performance and animal safety.

Calculating the Required Netting Length and Material

When calculating the required netting length and material for your electric netting system, it’s essential to consider the size of your farm and the density of your birds. A good rule of thumb is to add 1-2 feet to the perimeter of your fence line for each row of netting. For example, if you have a 100-foot long fence with two rows of netting, you’ll need approximately 200-240 feet of netting.

To determine the correct amount of material needed, consider the type and number of animals you’re protecting. A general guideline is to allow 2-3 square feet of netting per bird for small-scale operations and up to 5 square feet for larger farms. This will help ensure adequate coverage and prevent birds from escaping or getting entangled in the netting.

Keep in mind that electric netting systems come with different tensile strengths, which may impact your calculations. For instance, if you’re using a high-tensile net, you’ll need less material to achieve the same level of security as lower-tensile options. Be sure to consult the manufacturer’s guidelines and adjust your calculations accordingly.

When ordering your electric netting materials, it’s better to have some extra on hand to account for any unexpected gaps or repairs that may be needed. By taking these factors into consideration, you’ll be able to calculate the exact amount of material required for a secure and effective electric netting system.

Installing Your Electric Netting System Safely and Effectively

Installing an electric netting system can be a straightforward process if you follow some essential safety guidelines and best practices. To begin with, ensure that you’re wearing the right protective gear, including insulated gloves and safety glasses.

When connecting the netting to the energizer, make sure all connections are secure and not damaged in any way. A loose connection can lead to a failure of the system, which can be costly and time-consuming to fix. To avoid this, inspect each connection carefully before turning on the system.

Once your netting is connected, securing it to the ground or fence posts is crucial for preventing animals from finding weak spots. Use robust stakes or clips specifically designed for electric fencing, making sure they’re spaced evenly apart to maintain a consistent voltage. Regularly check your netting’s tension and adjust as necessary to ensure optimal performance.

Before turning on the system, perform a thorough inspection of all connections and electrical components. Test the system by using a voltage tester to confirm it’s functioning correctly. This will give you peace of mind knowing that your electric netting system is safe and effective.

Setting Up and Maintaining Your Electric Netting System

When setting up your electric netting system, ensuring a secure connection is crucial to preventing damage and maintaining effective protection for your flock. Let’s walk through some essential setup and maintenance tips.

Turning On and Testing Your Electric Netting System

Now it’s time to turn on and test your electric netting system. This is a crucial step to ensure that your fencing is functioning correctly and keeping predators out of your pasture. Before you start, make sure you’ve followed all the manufacturer’s instructions for assembly and installation.

To turn on your electric netting system, locate the energizer unit and connect it to a power source. Check that all connections are secure and not loose. Next, attach the fencing wires to the netting, making sure they’re properly spaced and not tangled. Now, set the voltage level according to the manufacturer’s recommendations for your specific system.

To test the system, use a non-contact voltage tester to ensure the fencing is electrified. Walk along the fence line while holding the tester, paying attention to any areas where the voltage may be weak or inconsistent. If you notice any issues, check your connections and adjust the tension on the wires as needed. This will help prevent damage to your system and keep it running efficiently.

Regular Maintenance Tasks

Regular maintenance is crucial to ensure your electric netting system continues to protect your poultry from predators and performs optimally. To keep your system running smoothly, set aside time each week for a quick checkup.

Start by inspecting the fence posts, wires, and corners for any signs of damage or wear. Look for frayed wires, loose connections, or bent posts that could compromise the system’s effectiveness. If you notice any issues, address them promptly to prevent further problems.

Don’t forget to regularly replace batteries in your energizer units or solar panels if they’re not self-sustaining. Most manufacturers recommend replacing batteries every 6-12 months depending on usage and weather conditions. Be sure to follow the manufacturer’s instructions for proper disposal of old batteries.

Additionally, keep an eye on the system’s voltage output, adjusting as needed to maintain optimal levels. A well-maintained electric netting system will reward you with years of reliable service and a healthy flock.

Troubleshooting Common Issues

If you encounter issues with your electric netting system, don’t panic – most problems can be resolved quickly and easily. One common issue is short circuits, which can occur if the fence is damaged, the wire is touching the ground, or there’s a buildup of debris on the fence.

To troubleshoot short circuits, first check for any visible damage to the fence. If you find any holes or tears, repair them immediately using the manufacturer’s recommended materials. Next, inspect the wire for any signs of wear or contact with the ground – if you notice any issues, rehang the netting or replace the affected sections.

Another potential issue is equipment failure. Make sure all parts are properly connected and tightened before use. Regularly check the condition of your energizer, fence posts, and netting to prevent premature wear. In case of animal escape attempts, inspect the fence for any gaps or weaknesses – reinforce these areas as needed using additional netting or support.

Remember to always follow safety guidelines when handling electrical equipment and take necessary precautions to avoid injury.

Safety Precautions When Using Electric Netting Systems

When setting up electric netting systems for your poultry, it’s essential to take extra precautions to ensure a safe and secure environment for both you and your birds. This section outlines critical safety measures to consider during installation.

Understanding Electric Shock Safety

Electric shock is a real risk when using electric netting systems for poultry, and it’s essential to understand how to minimize these risks. One of the primary causes of electric shock is poor grounding. A well-designed grounding system ensures that excess electrical energy is safely dissipated into the earth, reducing the likelihood of a shock.

When setting up your electric netting system, make sure to follow the manufacturer’s guidelines for grounding. This typically involves burying copper wires or rods deep into the soil near the fence posts. It’s also crucial to check the system regularly for damage and ensure that all connections are secure.

To further minimize the risk of electric shock, always wear safety equipment when working with the netting system. This includes insulated gloves, boots, and a face shield. In case of an emergency, have a first aid kit on hand and know what to do in case of a shock (see our emergency procedures guide for more information).

Protecting People and Animals

When working with electric netting systems, it’s crucial to prioritize both human and animal safety. Before setting up your system, ensure you’re aware of the voltage output and its potential effects on people. Familiarize yourself with the recommended safety distances between humans and the energized netting – typically 10-15 feet.

When handling or repairing electric netting, avoid using tools that may conduct electricity, such as metal ladders or pliers. Wear protective gear like gloves and safety glasses to prevent accidental shock exposure. Keep children and pets away from the area where you’re working with the system.

To prevent animal escape attempts and injuries:

* Regularly inspect your netting for damage or worn-out areas that may compromise its integrity.

* Ensure the netting is securely staked into the ground to prevent sagging or tripping hazards.

* Keep animals at a safe distance from the energized netting, as they can still attempt to touch it even with the shock-deterrent properties. Regularly monitor animal behavior and adjust your system accordingly.

By following these guidelines and exercising caution when working with electric netting systems, you’ll minimize risks for both humans and animals on your property.

Advanced Topics in Electric Netting Systems

Now that you’ve got a solid foundation in electric netting basics, let’s dive into some more advanced topics to help you optimize your setup for maximum protection and efficiency.

Integrating Other Farm Security Measures

When integrating an electric netting system with other farm security measures, you’re creating a robust defense against predators and potential intruders. Consider incorporating cameras into your setup to provide real-time monitoring of your flock’s surroundings. This can be especially useful for identifying and addressing potential issues before they escalate.

You may also want to explore alarm systems that alert you in case someone or something triggers the electric netting. These alarms can be linked to your phone or other devices, ensuring you receive immediate notification if there’s a breach. Lighting is another essential component to consider – motion-sensitive lights can deter predators and provide visibility after dark.

For added security, combine these measures with regular patrol checks around your property. By integrating an electric netting system with cameras, alarms, and lighting, you’ll create a multi-layered defense that minimizes the risk of losses due to predation or theft.

Using Electric Netting for Multi-Purpose Uses

Electric netting systems are incredibly versatile and can be used for multiple purposes beyond predator control. One of the most effective uses is as a containment fencing system. By using electric netting to enclose a specific area, you can prevent poultry from escaping or getting into areas where they shouldn’t be. This is particularly useful in areas with high predator activity or when managing large flocks.

For example, you can use electric netting to create a secure run for your chickens, ducks, or geese within a larger enclosure. This allows you to keep them safe and healthy while also preventing them from escaping into neighboring properties or causing damage to surrounding areas.

When using electric netting as a containment system, it’s essential to choose the right size and type of mesh for your needs. A minimum height of 3 feet is recommended, but taller nets can be used for larger flocks or in areas with more significant predator threats. Additionally, make sure to consider the terrain and any potential obstacles that may affect the net’s effectiveness.

Using electric netting as a containment system can also help prevent disease transmission by keeping birds from mixing with neighboring flocks. By isolating your flock, you can reduce the risk of disease transfer and maintain a healthier flock overall.

Frequently Asked Questions

What are some common mistakes to avoid when planning an electric netting system for my farm?

When designing your poultry electric netting system, remember that proper planning is key to effectiveness and safety. Common mistakes include underestimating the required netting length, failing to consider wind and weather factors, or neglecting to integrate other security measures.

Can I use electric netting for both containment and predator control purposes, or do I need separate systems?

Yes, you can definitely use electric netting for multiple purposes, including containment and predator control. However, it’s crucial to choose a system that meets the specific needs of your farm, taking into account factors like terrain, climate, and the type of birds being kept.

How often should I perform maintenance tasks on my electric netting system?

Regular maintenance is essential to ensure the effectiveness and safety of your poultry electric netting system. This includes checking for damage or wear, inspecting connections and wiring, and testing the system’s functionality at least once a month.

Can I use different types of wire or mesh for various sections of my farm, or should I stick to a single type?

Yes, you can choose different materials for different areas of your farm based on specific needs. For example, if you’re dealing with high-predation areas, using stronger wire or mesh may be necessary. Consult with experts and research local regulations before making decisions.

What are some safety precautions I should take when installing an electric netting system myself?

When setting up an electric netting system, it’s essential to exercise caution and follow proper protocols to avoid electrical shock. Always turn off the power source during installation or maintenance, use insulated tools and wear protective gear, and ensure that you have a clear understanding of how the system works before proceeding.